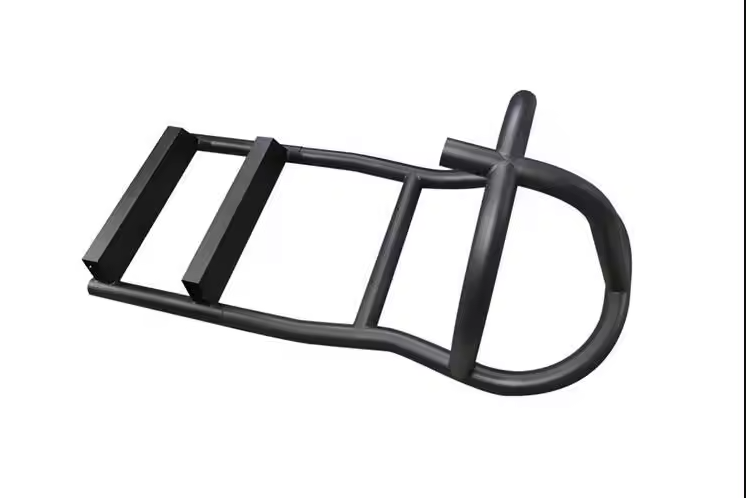

Round Tube Bending

November 8, 2023

U-bending pipe

November 9, 2023Examining the Advantages of Elbow Pipe Bending in Manufacturing

In the realm of manufacturing, precision and efficiency are essential for successful operations. Pipe bending is a critical process used in various industries, enabling the creation of complex and customized configurations. One such method, elbow pipe bending, has gained popularity due to its versatility and cost-effectiveness. This article aims to explore the advantages of elbow bending and its significance in manufacturing processes.

1. Precision and Customization of Elbow pipe bending :

It offers manufacturers the ability to create highly precise and customized pipe configurations. It allows for the production of elbows with specific angles and radii, accommodating the unique requirements of various applications. Whether it’s for plumbing, HVAC systems, or industrial machinery, elbow bending ensures accuracy in fitting and positioning, reducing the need for additional components or corrective measures.

2. Enhanced Flow Efficiency:

The smooth curvature achieved through elbow pipe bending significantly improves the fluid flow within pipework systems. By minimizing sharp angles or corners, frictional losses and pressure drop can be minimized. This leads to increased operational efficiency and reduced energy consumption. Industries such as oil and gas, chemical processing, and water distribution benefit from improved flow rates and enhanced system performance.

3. Space Optimization:

It provides a practical solution to space constraints, particularly in compact installations or confined areas. By utilizing elbows with varying angles, it becomes possible to navigate around obstacles, efficiently routing pipework through restricted spaces. This flexibility allows for more efficient allocation of available real estate within manufacturing facilities, resulting in optimized layouts and improved overall productivity.

4. Durability and Longevity:

Manufacturers often face challenges related to the durability and longevity of their piping systems. Elbow pipe bending addresses these concerns effectively. By eliminating the need for multiple joints and connectors, there are fewer potential points of failure. Furthermore, properly bent elbows distribute stress evenly along the entire structure, reducing the risk of leaks, fractures, or breakages. This enhances the overall reliability and lifespan of the pipework, leading to lower maintenance costs and increased operational uptime.

5. Cost-effectiveness Elbow pipe bending :

It offers significant cost advantages compared to alternative methods. By reducing the number of components required for a piping system, material costs can be minimized. Additionally, the elimination of additional connectors or fittings reduces labor costs associated with assembly and installation. The ability to create custom configurations directly reduces waste, further optimizing expenditure. These cost benefits make elbow pipe bending an attractive choice for manufacturers looking to improve their bottom line without compromising quality.

Conclusion:

It has emerged as a valuable technique in manufacturing processes. Its advantages, including precision, enhanced flow efficiency, space optimization, durability, and cost-effectiveness, contribute to improved system performance and reduced operational expenses. As manufacturing continues to evolve, the adoption of elbow pipe bending will likely increase, enabling industries to meet the demands of complex applications effectively. Manufacturers should consider incorporating this versatile technique to enhance their productivity and maintain a competitive edge in the market.