Elbow pipe bending

November 9, 2023

Coil Pipe Bending

November 10, 2023Unraveling the Benefits of U-Bending Pipe Manufacturing

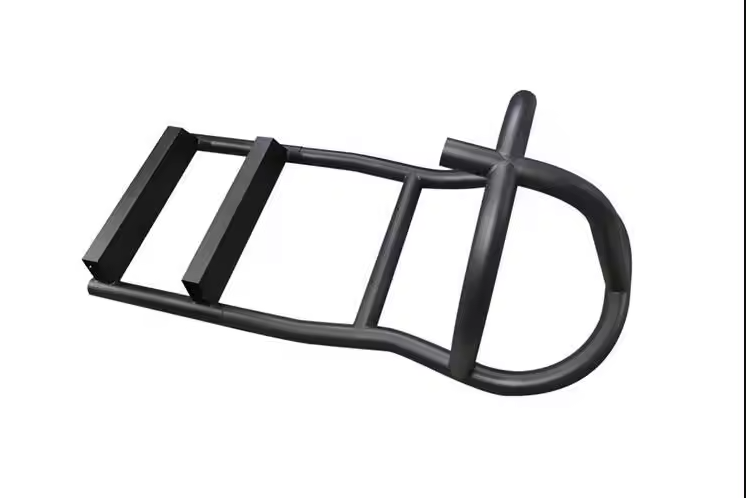

In the world of industrial manufacturing, precision and efficiency are paramount. A crucial process in various industries is pipe bending, which allows for the creation of intricate and customized configurations. One specific method, known as U-bending pipe manufacturing, has gained popularity due to its versatility and effectiveness. This article aims to explore the advantages of U-bending pipe manufacturing and its significance in modern industrial processes.

1. Customization and Versatility:

U-bending pipe manufacturing offers manufacturers the ability to create highly customized and versatile pipe configurations. By utilizing this technique, pipes can be bent into U-shapes with specific angles and radii, catering to the unique requirements of various applications. Whether it’s for heat exchangers, condensers, or other intricate systems, U-bending allows for precise fitting and positioning, eliminating the need for additional components or complex assembly processes.

2. Enhanced Heat Transfer Efficiency:

The U-shaped configuration achieved through U-bending pipe manufacturing significantly enhances heat transfer efficiency within heat exchange systems. The curved structure promotes a more uniform flow distribution, ensuring optimal heat dissipation across the entire surface area. As a result, the overall thermal performance of heat exchangers and condensers improves, leading to better energy efficiency and reduced operational costs.

3. Space Optimization of U-bending pipe:

Such pipe manufacturing provides an efficient solution to space constraints, particularly in compact installations or restricted areas. The unique U-shaped design allows for easier routing of the piping system around obstacles, maximizing available space and enabling seamless integration into complex machinery or equipment. By optimizing space usage, manufacturers can achieve optimal layouts, enhance productivity, and improve overall operational efficiency.

4. Strength and Durability:

The U-bending pipe manufacturing process ensures the strength and durability of the pipes, even after extensive bending. The technique involves carefully controlled bending, which minimizes the risk of structural weakness or defects. The resultant U-shaped pipes maintain their mechanical integrity, displaying resistance to stress, vibration, and corrosion. As a result, U-bent pipes offer enhanced longevity, reducing maintenance costs, and contributing to the overall reliability of industrial systems.

5. Cost-effectiveness U-bending pipe:

This pipe manufacturing offers significant cost advantages compared to alternative methods. The ability to create custom U-shaped configurations directly minimizes material waste. By eliminating the need for additional connectors or fittings, U-bending reduces the overall number of components required for assembly. This simplification streamlines the production process, lowers labor costs, and enhances overall cost-effectiveness. Manufacturers can achieve optimal results while maintaining profitability.

Conclusion:

U-bending pipe manufacturing has emerged as a valuable technique in modern industrial processes. Its benefits, including customization, enhanced heat transfer efficiency, space optimization, strength, and cost-effectiveness, contribute to improved system performance and reduced operational expenses. As industrial manufacturing continues to advance, the adoption of U-bending pipe manufacturing is expected to increase, allowing industries to meet complex requirements effectively. Manufacturers must consider incorporating this versatile technique to optimize their productivity and gain a competitive edge in the market.