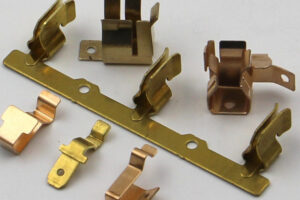

The process of Sheet Metal Brass Fabrication

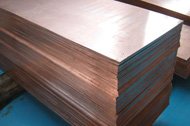

Sheet metal brass fabrication is a specialized process that involves shaping and manipulating brass sheets into various components and products. Brass, known for its durability, corrosion resistance, and aesthetic appeal, is a popular choice in industries such as automotive, construction, and electronics. This article delves into the intricacies of sheet metal brass fabrication, exploring its techniques, applications, and importance in modern manufacturing.

Properties of Brass:

Brass, a metal alloy composed of copper and zinc, exhibits unique properties that make it ideal for fabrication purposes. Its malleability, ductility, and conductivity allow for easy forming and shaping into intricate designs. The distinctive golden hue of brass adds a touch of elegance to finished products, making it a preferred material in decorative applications.

In the field of sheet metal brass fabrication, various types and grades of brass are utilized for different purposes:

- Leaded Brass:

Leaded brass is composed of about 3.5% lead as an alloying element, which enhances its strength for fabrication purposes. This type of brass is commonly used in the production of fittings, architectural hardware, bearings, and general machine parts. - Cartridge Brass:

Cartridge brass is an alloy made from a combination of copper and zinc in a 70:30 ratio, resulting in a distinctive yellow color. Sheets made from cartridge brass are renowned for their excellent workability and ductility, making them ideal for plating operations. - Naval Brass:

Naval brass is a composition of copper, zinc, tin, and lead, primarily employed in marine applications such as manufacturing propeller shafts and other marine hardware. Although tin and lead make up less than one percent of the alloy, they play a crucial role in enhancing the mechanical properties of naval brass.

For further information and resources on sheet metal brass fabrication, please refer to the following sources:

Properties of Sheet Metal Brass Beneficial for Fabrication Processes

Sheet metal brass possesses unique properties that make it suitable for various fabrication techniques including forging and forming. These properties include:

1. Antimicrobial Properties

Sheet metal brass components have the ability to inhibit bacterial growth and virus proliferation on their surfaces. This feature is particularly valuable in applications where hygiene is critical, such as in the production of medical instruments and hospital furnishings.

2. Exceptional Durability

One of the key characteristics of sheet metal brass is its remarkable durability, allowing it to withstand wear and tear effectively. This durability makes it ideal for fabricating components used in demanding environments like construction projects and musical instrument manufacturing.

3. Excellent Electrical and Thermal Conductivity

Brass is widely employed in fabricating components for electrical applications due to its superior conductivity. Moreover, brass can endure high temperatures, making it suitable for use in applications sensitive to heat.

4. Versatile Finishing Options

Sheet metal brass can be finished in a variety of ways, including mill, long grain, satin, and mirror finishes. This versatility in surface finishes enables the fabrication of decorative components and the implementation of intricate designs.

5. Enhanced Resistance

Thanks to its elemental composition, sheet metal brass exhibits improved resistance to corrosion, tarnishing, and chemical damage. As a result, components made from sheet metal brass are well-suited for use in corrosive environments.

6. High Malleability

Sheet metal brass offers exceptional malleability, facilitating various fabrication operations such as cutting, punching, bending, and drilling. This malleability ensures that machining processes can be carried out smoothly without causing detrimental effects like cracking.

Sheet Metal Brass Fabrication Process

-

Cutting

– The sheet metal brass fabrication process begins with cutting the raw brass sheets into the required shapes and sizes.

– Advanced machinery like laser cutters are used to ensure precise and clean cuts.

-

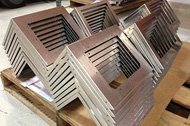

Bending:

– After cutting, the brass sheets are bent to achieve the desired angles and shapes.

– CNC presses are commonly used to bend the sheets accurately according to the design specifications.

-

Forming:

– In this stage, the bent brass sheets are further shaped and formed into specific components.

– Skilled technicians may use tools like hydraulic brakes to manipulate the metal into intricate forms.

-

Welding:

– Welding is a crucial step in joining the different components together to create a unified structure.

– Techniques such as TIG welding or MIG welding may be employed to join the brass pieces securely.

Sheet Metal Brass Fabrication Surface Treatments:

During the fabrication process of sheet metal brass, applying surface treatments serves two primary purposes:

- Enhancement of Corrosion and Abrasion Resistance

- Increase in Coating Thickness

Surface Treatment Methods:

Brass Galvanization

– Involves immersing brass parts in molten zinc to create a protective coating with exceptional corrosion resistance.

Advantages:

– Enhances corrosion resistance.

– Cost-effective method.

– Provides a long-lasting and uniform finish.

– Quick process.

Applications

– Electronic equipment like electronic boxes.

– Automotive components.

– Machine parts and toolboxes.

– Light fixtures such as chandeliers.

Brass Powder Coating

– This method involves electrostatically applying dry powder over the brass substrate to create a durable coating upon curing.

Advantages:

– Allows for color application and different textures.

– Eliminates dripping or paint runs.

– Quick curing time.

– Results in a thick and even surface finish.

Applications:

– Vehicle components.

– Outdoor signage and furniture.

– Doors and windows.

– Home appliances.

Brass Anodizing

– Uses passive electrolysis to thicken the surface layer of brass for enhanced corrosion protection.

Advantages:

– Increased surface hardness.

– Achieves a smooth and uniform coating.

– Dyeing adds color for enhanced appearance.

– Improved resistance to corrosion, wear, and abrasion.

Applications:

– Construction materials like roofs.

– Industrial structures such as oil platforms.

– Home appliances like white goods.

– Scientific instruments and computer hardware.

E-Coating for Brass

– Involves applying a thin layer of epoxy paint over the brass substrate by passing an electric current through a solution containing desired coating pigments.

Advantages:

– Acts as a primer for other surface treatments.

– Ensures a durable and uniform thickness.

– Can increase surface thickness.

– Improves corrosion resistance.

Applications:

– Hardware tools and equipment.

– Marine and automotive parts.

These various surface treatment methods play a crucial role in enhancing the properties of brass components used in a wide range of applications.

Sheet Metal Brass Fabrication Machinery Used:

– Laser cutters: for precision cutting of brass sheets.

– CNC presses: for accurate bending of brass components.

– Hydraulic brakes: for shaping and forming the brass sheets.

Sheet Metal Brass Fabrication Workforce:

– Skilled technicians and engineers collaborate to ensure the fabrication process meets the specific requirements of the project.

– Their expertise and attention to detail play a vital role in transforming raw brass sheets into customized components.