What is Metal Fabrication?

Metal fabrication refers to the process of creating products or structures by cutting, bending, and/or assembling metal materials. It is considered a value-added process, as it involves transforming raw metal materials into finished products or structures.

Metal fabrication refers to the process of creating products or structures by cutting, bending, and/or assembling metal materials. It is considered a value-added process, as it involves transforming raw metal materials into finished products or structures.

The fabrication process typically consists of three phases: design, fabrication, and installation. In the design phase, shop drawings are created according to the intended measurements. The fabrication phase involves cutting, bending, and/or assembling the metal materials, while the installation phase involves putting together the end product or structure, either partially or fully.

Metal fabricators work with various raw materials, such as plate metal, expanded metal, welding wires and rods, and cast metal. Fabrication is a crucial step in creating any type of finished metal part or structure.

Fabricators generally work in machine shops or dedicated metal fabrication shops that specialize in metal preparation and fabrication. Although less common today, blacksmiths, boilermakers, and ironworkers have historically been considered metal fabricators.

Metal fabrication can be segmented into various types, including industrial, structural, and commercial. In this post, we will discuss these three common types of metal fabrication.

Industrial Metal Fabrication

As you might have already guessed, industrial metal fabrication involves the process of combining various components or assemblies, usually made from sheets or plates, to create industrial products.

Fabricators in this industry typically cater to sectors such as aerospace, alternative energy, material handling, pollution control engineering, water treatment, automotive, and many others. The products they manufacture are usually quite large and often encompass items like tanks, silos, and heavy machinery parts.

It’s worth noting that, unlike structural metal fabrication, which we will explore in the next section, industrial metal parts are generally used in conjunction with each other to serve their purpose.

Structural Metal Fabrication

High-strength structural metal is a prevalent material in the construction industry, regardless of whether the project is commercial, industrial, or residential. Structural metal fabrication entails creating metal parts for these applications, such as I-beams.

Steel is the most favored metal for structural fabrication due to its excellent strength-to-weight ratio. Nearly every construction project incorporates steel in some form or another.

In commercial settings, steel often forms the foundation. Some renowned structures constructed with structural steel include the Empire State Building in New York City, the Sydney Harbour Bridge, and Dubai’s Burj Khalifa, the tallest building in the world.

Here are some examples of metal parts used in structural projects:

- Towers, which are custom-made facility parts that enhance production capabilities.

- Platforms, which are commonly used in loading bays, storage areas, ramps, or decks in various facilities.

- Walkways, which must adhere to OSHA standards in industrial environments.

- Stairs, which require durability and strength in residential, commercial, or industrial settings.

- Structural components that comprise the main framework of a building, such as trusses, girders, and beams.

Commercial Metal Fabrication

Commercial metal fabrication involves creating parts that are commonly installed in commercial settings, such as restaurants, stores, public spaces, and municipal buildings. The range of commercial metal products includes:

- Guardrails

- Awnings

- Shelving units

- Sinks and other appliances

- Conveyor systems

Additionally, decorative or ornamental metal fabrication is another aspect of commercial metalwork. These metal products are designed to enhance the aesthetics of commercial buildings and improve their curb appeal.

Unlike structural and industrial metal parts, commercial metal components tend to be smaller and more intricate. However, they play a crucial role in the functionality and safety of commercial entities, ensuring the well-being of employees and customers alike.

Sheet Metal Fabrication Manufacturer

As a ISO 9001:2008 certified sheet metal fabricators in China, we provide customers with stable and reliable products and competitive prices, and we offer a cost-effective and on-demand solution for your manufacturing requirements. The services range from standard gauge to special gauge, and we will responsible and manage for every step of materials, manufacturing, inspection, packaging and delivery whether it is low-volume prototypes and high-volume production runs. Our development and design department can provide custom service of design and package to your exact specifications. We support various formats of drawing files from images (PDF/JPG/JPEG/PNG/GIF), 2D drawings (CAD/DXF) to 3D drawings (STP/STEP/IGS/IGES/XT/SLDPRT).

Main Metal Fabrication services

Production Ability

Tolerance :+/-0.01 mm ~ +/-0.05 mm, to be discussed

Surface treatment: polish( buff, vibration,electro-polish and so on),plating (Zinc,Silver,Brass,Tin and so on),Powder coating, Planting

Size: from 3 mm to 1500 mm. Can be customized and to be confirmed.

Sheet Metal Materials

Sheet metal processing materials are generally used cold-rolled plate (SPCC), hot-rolled plate, galvanized plate (SHCC) (SECC, SGCC), copper (CU) brass, copper, beryllium copper, aluminum (6061, 5052, 1010, 1060, 6063, aluminum etc.), stainless steel (wire drawing, mirror, fog). According to the product function, selection of different materials, generally from product use and cost to consider.

Metal Fabrication Application

The processing steps of the sheet metal workshops are as follows: the pre product test, the product processing test and the production of the product batch. In the process of processing the product, we should communicate with the customers in time, and get the evaluation of the corresponding processing, and then make the production of the product in batch.

Sheet metal processing is widely used in both daily life and industrial production. For example, it can be used to make chimneys, iron drums, fuel tanks, ventilation pipes, elbow reducers, round and square shapes, funnel shapes, etc.

The main processes include shearing, bending and trimming, bending and forming, welding, riveting, etc., which require certain geometric knowledge. Sheet metal parts are thin sheet metal parts, which can be processed by stamping, bending, stretching and other means. A general definition is that the thickness of the part remains unchanged during the processing process. The corresponding parts are castings, forged parts, machined parts, etc

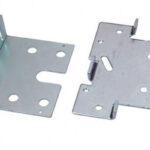

Representative Sheet Metal Sample

We have been offering Custom Metal Fabrication services for oversea customers for many years. A lot of customer enjoyed the business with us from the very beginning.

Due to our fast delivery, quality items, low cost, many clients are pleased to offer more opportunity for us.The samples showing here is for your reference only. Do Not sell directly.We provide custom serives.