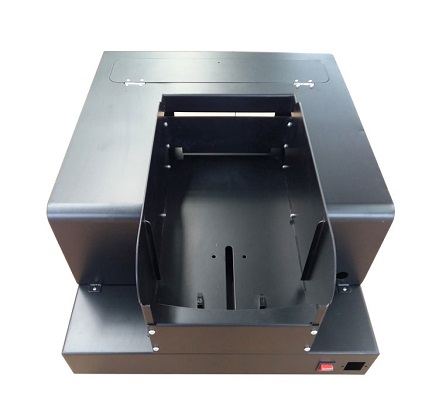

Sheet metal enclosure

September 25, 2020

Custom aluminum sheet fabrication

November 18, 2020Stainless steel enclosure

Stainless steel enclosure are cially suitable for corrosive environments installations where hygieneis essential in chemical and food industries, etc. Monobloc watertight AISI304 stainless steel enclosures. Types AISI316(resistant to concentrated acids and halogen based agents)also available on request.

We are professional company of sheet metal products and customize control box.we have rich experience in structure design, circuit design and all machining procedure. With talented staff, advanced equipment and improved process inspecion system, we are confident in the quality of every piece of work. Also, our products are popular in both overseas and domestic market in terms of wide range, reasonable prices and good quality. The mission of our company is ‘ Creation for Industry’ that contributes to our continuous development.

Sheet Metal Fabrication

| Product Name: | China factory outdoor waterproof sheet stainless steel electric enclosure meter junction metal box |

| Material: | SPCC, SECC, SHCC, Aluminum, 201SS, 304SS, 316SS, 430SS, Copper, etc. |

| Surface Treatment: | Powder coat, paint, electroplate, Anodize, polishing, brushing, galvanize, silk screem, etc. |

| Processing Craft: | Laser Cutting, CNC Punching, CNC Bending, Tig Welding, Mig Welding, Riveting, Grinding, Stamping |

| Drawings Format: | Solidworks, Pro/Engineer, AutoCAD, PDF, JPGE, PNG, etc. |

| Mean Market: | China Taiwan, China Mainland, Brazil, USA, England, Gemany, Russia, Australia, Egpyt |

| Service Type: | OEM & ODM |

| Weldon History: | Since 2006, about 10-years sheet metal fabrication Experience |

| Business Type: | Manufacturer |

| Factory Area: | 6000 Square meters |

| Certification: | ISO 9001:2008 |

Custom stainless steel enclosure

1.Two years warranty since each sales

2.Tracking every step until customer receive the goods in his/her satisfaction

3.Shipping forwarder choice at customer’s requirements

4.Should’ve any broken parts received, the compensation of new parts will be delivered to customer attached in the next order

5.Always being a tutor at your side when you’re using our products

Available processing (Technique)

We are committed to provide high quality services to our customers and serviced many different industries, including Electronics, Medical, Communications, Rugged Systems and Commercial Industries, etc. We provide a wide range of services, which include:

– CNC Turret Punch Press Stampings.

– CNC Press Brakes.

– CNC Shear.

– CNC Machining Centers.

– CAD – CAM Design.

– Full Range of Sheet Metal Materials.

– Welding: TIG, MIG and Spot Welding. ( Outstanding Quality )

– Mechanical Assembly.

– Silk – Screening and Deburring.

– Bar Coding and JIT Delivery worldwide.

We have very strict QC & QA to insure our workers working in a safe and neat environment.

No.1 workshop mainly are Automation equipment, such as laser cutting machine, CNC punching machine, shearing machine, bending machine, etc.

No.2 workshop are dealing with the surface treatment, including powder coat and painting.

For the Environmental Protection requirement, we have to separate two workshops.