Metal Tube Bending

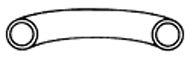

We have many kinds of CNC tube bending die for round pipe, square tube, flat iron, angle steel, channel steel and special-shaped material and so on. The section drawing and bending equipment and mould basically cover the requirements of standard arc, ellipse arc, S bend, rotary modeling and so on.

The products are widely used in the fields of building curtain wall, indoor and outdoor decoration, road and bridge, auto parts, furniture accessories, bathroom products and all other products that need curved arc molding.

Metal tube bending is a tube fabrication process for metal tube, pipe, bar, rod and profile permanent forming through the bending machine and die to form a fixed shape. It is widely used in industries of furniture, HVAC, automotive, machinery, equipment, construction and more. We offer the tube bending service for materials of the steel, stainless steel, aluminum, brass and copper. And there are many shapes and sizes of materials for your choice, such as: round, square, rectangular, hexagon, oval, and etc.

Tube and Pipe Bending Service

Tube bending techniques are primarily categorized into two methods: hot tube bending and cold tube bending. Each approach has its unique advantages and considerations, depending on the application and material requirements.

Hot Tube Bending

Hot tube bending, as the name implies, involves heating the tube to a high temperature to make the bending process easier. When metals are heated, they become softer and more malleable, allowing them to bend with less force and reducing the risk of cracking or breaking.

However, one significant drawback of this method is thermal expansion. As metals expand when heated, the final dimensions and bend angles may differ once the material cools, potentially leading to deviations from the desired specifications.

Cold Tube Bending

In contrast, cold tube bending is performed at room temperature, eliminating the need for heating the metal tubing. This method offers greater precision, as there are no temperature-induced changes to the material’s dimensions. The absence of heat ensures that the final product maintains its intended shape and accuracy, making it ideal for applications where tight tolerances are critical.

Both methods have their place in manufacturing, with the choice depending on factors such as material type, bend complexity, and dimensional accuracy requirements.

The above information are according to our many year experience in this field. If you wish to get more detail about this process, please see more about tube bending on WIKI.

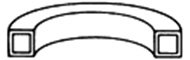

Bar and Flat Bending Service

We specialize in bending and rolling services, with a strong track record in bar rolling. Bar rolling involves transforming flat bar stock into precisely curved components, offering a cost-effective and efficient alternative to traditional methods like laser cutting or plasma burning.

One of the key benefits of bar rolling is its ability to produce flat rings and ring segments with minimal material waste. Compared to cutting parts from a sheet, this process significantly reduces scrap, saving you material, time, and money. Despite being a bending process, bar rolling delivers the same high level of accuracy as other manufacturing methods.

At Linders, we operate a variety of advanced rolling and bending machines, enabling us to choose the ideal equipment and tooling for your specific bar rolling requirements. Our state-of-the-art technology ensures that distortion—a common challenge in bending processes—is kept to a minimum. This allows us to handle large flat bars with exceptional precision. By matching your project to the right machine, we minimize material loss during trimming, further reducing your costs.

Our bar rolling capabilities include:

– The easy way: Rolling perpendicular to the bar’s largest dimension.

– The hard way: Rolling parallel to the bar’s largest dimension.

Both methods are executed with tight tolerances in all directions.

Additionally, we can accommodate complex projects requiring multiple bends or variable radii. Our expertise in compound bends, combined with our extensive range of rolling equipment, ensures we can meet even the most demanding delivery schedules.

Contact our experienced team today to request a quote for your application.

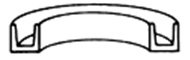

Steel Profile and Section Bending Service (Angle, C Channel, T Bar, I Beam, H Beam)

Our success in profile bending technology is built on decades of experience, advanced state-of-the-art machinery, and unwavering commitment to high-quality standards. These factors enable us to deliver cost-effective production solutions tailored to your needs. Looking ahead, we aim to further refine these concepts to optimize efficiency for smaller production runs.

Our Key Advantages:

- Versatile Material and Profile Capabilities : We bend parts from a wide range of materials, including common structural steels, high-strength steels, and stainless steels. Our expertise extends to countless cross-sections—open or welded, symmetrical or asymmetrical, HF or laser-welded, and thin or thick-walled profiles.

- Flawless Quality: Even with complex shapes, we maintain exceptional part geometry and surface quality.

- Tight Bending Radii: We achieve the tightest bending radii to meet demanding design requirements.

– **High Precision**: Our processes ensure dimensional accuracy and fit, facilitating seamless further processing in your operations. - Dimensional Bending: We specialize in intricate 3D bending for complex part geometries.

- In-House Tool Shop: Our in-house tool shop enhances our flexibility and efficiency. By integrating simulation technology, tool design, and tool production under one roof, we minimize unnecessary tool adjustment cycles and deliver optimized solutions from the start.

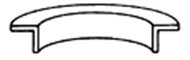

Tube Coiling Service

At MetalfabricationChina, we specialize in delivering consistent, high-quality tube coiling services designed to support your business’s long-term growth and profitability.

Our capabilities include the use of both standard roll bending tooling and custom coilers, allowing us to create coils in a variety of sizes, configurations, and materials. We work with:

– Steel

– Stainless Steel

– Copper

– Aluminum

– Custom Extrusions

– Square Tubing

– Solid Rod

Whether your project requires precision, versatility, or unique material specifications, we have the expertise and equipment to meet your needs.

Custom Tube Bending & Fabrication Manufacturer

As a professional manufacturer of metal tube fabrication in China. We offer a stable, reliable and competitive prices products for your application. We will manage your manufacturing projects from design, manufacture, inspection, assembly, packaging to delivery. If you are looking for a real factory to work the metal tube bending job, we will be your ideal partner. Please send Email to info@metalfabricationchina.com to get a quotation for tube bending.

The Common Materials for Metal Tube Bending:

The Common Materials for Tube Saw Cutting:

Materials: Steeld, Stainless Steel, Aluminum, Copper and Brass

Type: Tube, Pipe, Rod, Bar, Flat

Size: Round, Square, Rectangular, Hexagon, Oval

We can also provide the other value-added service as follows:

1. Coiling, Tube End Forming, Hole Drilling

2. Welding Service: SMAW, GTAW, GMAW, TIG, MIG/MAG

3. Heat Treatment

4. Surface Finishing

(1) Buffing and Polishing (Metal Mirror Polished, Brushed Metal Finishing)

(2) Sandblasting, Pickling and Phosphating

(3) Powder Coating, Anodizing, Zinc Plating, Hot Dip Galvanized, Chrome Plating and Nickel Plating

(4) Assembly

4. Other Services

Sheet Metal Fabrication

Metal Stamping

Plastic Molding

About RFQ of Bending Service

1. Materials Grade: The different countries has different materials standards and grades, such as ASTM, API, DIN, BS, JIS, AS, NZ, and more. Due to cost of materials and procurement considerations, we usually recommend that customers use the same level of the Chinese grade materials (GB standards) as an substitute material. We will provide the chemical composition and mechanical properties of the corresponding materials to you reference.

2. Sometimes there are some materials need to be customized due to inventory reasons, it will be limited by the minimum order quantity of the products.

3. The bent parts need to match bent molds and fixtures tooling for production. Usually if you paid the mold cost, we will provide you with free samples to you test.

4. Materials Size: Millimeters (mm) is the most commonly used size unit in China. We will convert the inch size and gauge size to metric size based on the customer’s drawings, then send the outside diameter, inside diameter or thickness to customer confirmation.

a. 1 inch = 2.54cm

b. 1 foot = 12 inch = 30.48cm

c. Gauge to Thickness Chart