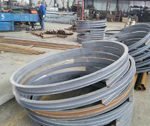

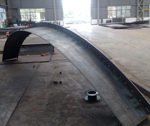

Sheet Metal Rolling

The sheet metal rolling is a metal forming process in sheet metal fabrication. It’s used one or more pairs of rolls to to achieve the curved effect of metal plate. Usually the rolling processing need collocation the other manufacturing processes to produce the finished product, such as cutting, bending, drilling, welding and surface finishing. It is widely used in manufacturing to tank, cylinder, cover, protector and so on. The rolling processing is a roughing method, so the product quality depends on the worker production experience and equipment performance.

At present, the control rolling process is widely used in plate production. Generally, the single stage rolling mill adopts the two stage rolling, and the middle part uses an air cooling stage to ensure the open rolling temperature of the second stage rolling. The process improves the performance of the product, but also reduces the output of the rolling mill. In order to reduce the yield loss caused by the temperature waiting stage, many manufacturers at home and abroad have adopted many cross rolling methods to improve the productivity of the rolling mill. In the process of specific control, it is necessary to consider the matching relationship between rolling time and temperature time, the length limit of the rolled piece, the control of the rolling rhythm and the rational scheduling of space, so as to reduce the standby time of rolling mill to a maximum and increase the output.

The Common Materials for Sheet Metal Rolling:

Steel Plate, Stainless Steel Plate, Aluminum Plate, Copper Plate, Brass Plate

In addition to sheet metal rolling, we can also provide cutting, bending, welding, assembly, surface finishing and packaging service. Feel free to contact us for more details.

The other value-added service as follows:

1. Hole Drilling, Grinding, Machining, Riveting

2. Metal Sheet Cutting, Bending and Stamping

3. Welding Service: SMAW, GTAW, GMAW, TIG, MIG/MAG

4. Heat Treatment

5. Surface Finishing

(1) Buffing and Polishing (Metal Mirror Polished, Brushed Metal Finishing)

(2) Sandblasting, Pickling and Phosphating

(3) Powder Coating, Anodizing, Zinc Plating, Hot Dip Galvanized, Chrome Plating and Nickel Plating

(4) Assembly

We also provide others value-added services, such as design for manufacturability, technology support, quick-turn prototyping, machining and tooling make in-house and more