Pipe Supplier and manufacturer

We are not only a professional sheet metal parts manufacturer, but also we are Pipe Supplier and manufacturer. Therefore,we also provide high-quality steel pipes of various specifications.

We have many professional steel pipe production lines. From blanking, welding, polishing and cutting, each link is strictly controlled to provide steel pipes with high precision and surface quality.

What is steel Pipes

Steel with a hollow section whose length is much larger than the diameter or circumference. It is divided into circular, square, rectangular and special-shaped steel pipes according to the section shape; It can be divided into carbon structural steel pipe, low alloy structural steel pipe, alloy steel pipe and composite steel pipe according to the material; It can be divided into steel pipes for transmission pipeline, engineering structure, thermal equipment, petrochemical industry, machinery manufacturing, geological drilling, high-pressure equipment, etc; According to the production process, it can be divided into seamless steel pipe and welded steel pipe. Seamless steel pipe can be divided into hot rolling and cold rolling (drawing). Welded steel pipe can be divided into straight seam welded steel pipe and spiral seam welded steel pipe.

Steel pipe is not only used to transport fluid and powdery solid, exchange heat energy, manufacture mechanical parts and containers, but also an economic steel. Using steel pipes to manufacture building structure grids, pillars and mechanical supports can reduce weight, save 20~40% of metal, and realize factory mechanized construction. Using steel pipes to make highway bridges can not only save steel materials and simplify construction, but also greatly reduce the area of protective coating, save investment and maintenance costs.

Professional Pipe Supplier and manufacturer

The steel pipes are divided into seamless steel pipes and welded steel pipes. The production process of seamless steel pipe is to thread solid tube blank or steel ingot into hollow capillary, and then roll it into steel pipe of required size. Different piercing and rolling methods are used to produce seamless steel tubes. The production process of welded steel pipe is to bend the tube blank (steel plate or strip) into a tube, and then weld the gap to become a steel pipe. Different forming and welding methods are used to produce welded steel pipes.

The steel pipes are divided into seamless steel pipes and welded steel pipes. The production process of seamless steel pipe is to thread solid tube blank or steel ingot into hollow capillary, and then roll it into steel pipe of required size. Different piercing and rolling methods are used to produce seamless steel tubes. The production process of welded steel pipe is to bend the tube blank (steel plate or strip) into a tube, and then weld the gap to become a steel pipe. Different forming and welding methods are used to produce welded steel pipes.

Seamless steel pipes are mainly produced by hot rolling. Extrusion method is mainly used to produce low plasticity high alloy steel pipe or profiled steel pipe and composite metal pipe that are difficult to pierce. The cold rolling and cold drawing methods can continue to process the hot rolled tubes into small diameter and thin-walled steel tubes. The welding process of steel pipe is simple, the production efficiency is high, the cost is low, and the product variety is expanding day by day.

Classification of steel pipes

By production method

According to the production method, steel pipes can be divided into two categories: seamless steel pipes and welded steel pipes. Welded steel pipes are referred to as welded pipes for short.

1. Seamless steel tubes can be divided into hot rolled seamless tubes, cold drawn tubes, precision steel tubes, hot expanded tubes, cold spun tubes and extruded tubes according to production methods.

Bundled steel pipes

Bundled steel pipes

Seamless steel pipes are made of high-quality carbon steel or alloy steel, which can be hot rolled or cold rolled (drawn).

2. Welded steel pipes are divided into furnace welded pipes, electric welding (resistance welding) pipes and automatic arc welded pipes due to their different welding processes. They are divided into straight seam welded pipes and spiral welded pipes due to their different welding forms. Their end shapes are also divided into circular welded pipes and special-shaped (square, flat, etc.) welded pipes.

Welded steel pipes are welded from rolled steel plates with butt or spiral seams. In terms of manufacturing methods, they are also divided into welded steel pipes for low pressure fluid transportation, spiral electric welded steel pipes, directly rolled welded steel pipes, electric welded pipes, etc. Seamless steel pipes can be used in various industries, such as liquid and gas pipelines. Welding pipe can be used for water pipe, gas pipe, heating pipe, electrical pipe, etc.

Material classification

The steel pipe can be divided into carbon pipe, alloy pipe, stainless steel pipe, etc. according to the pipe material (i.e. steel type).

Carbon pipes can also be divided into ordinary carbon steel pipes and high-quality carbon structural pipes.

Alloy pipe can be divided into low alloy pipe, alloy structure pipe, high alloy pipe and high strength pipe. Bearing tube, heat and acid resistant stainless steel tube, precision alloy (such as Kovar alloy) tube and high temperature alloy tube.

Classification of coating characteristics

The steel pipe can be divided into black pipe (non coated) and coated pipe according to the surface coating characteristics.

The coated pipe includes galvanized pipe, aluminum plated pipe, chrome plated pipe, aluminized pipe and other steel pipes with alloy coating.

Coated pipes include externally coated pipes, internally coated pipes and internally and externally coated pipes. The coatings commonly used are plastic, epoxy resin, coal tar epoxy resin and various glass based anti-corrosion coatings.

Galvanized pipe is also divided into KBG pipe, JDG pipe, threaded pipe, etc.

Classification Purpose Classification

1. Pipes for pipes. Such as: seamless pipe for water, gas pipe, steam pipe, oil transmission pipe, oil and gas trunk pipe. Faucet hose and sprinkler pipe for agricultural irrigation.

2. Pipes for thermal equipment. Such as boiling water pipes and superheated steam pipes for general boilers, superheated pipes, large smoke pipes, small smoke pipes, arch brick pipes and high temperature and high pressure boiler pipes for locomotive boilers.

3. Pipe for mechanical industry. Such as aviation structural pipe (round pipe, oval pipe, flat oval pipe), automotive semi axle pipe, axle pipe, automotive tractor structural pipe, tractor oil cooler pipe, agricultural machinery square pipe and rectangular pipe, transformer pipe and bearing pipe.

4. Pipes for petroleum geological drilling. Such as: oil drilling pipe, oil drill pipe (kelly and hexagonal drill pipe), drill stem, oil tubing, oil casing and various pipe joints, geological drilling pipe (core pipe, casing, active drill pipe, drill stem, collar and pin joint).

5. Pipes for chemical industry. Such as: petroleum cracking pipe, pipe for heat exchanger and pipeline of chemical equipment, stainless acid resistant pipe, high-pressure pipe for chemical fertilizer and pipe for conveying chemical medium.

6. For other departments. Such as: container pipe (high pressure gas cylinder pipe and general container pipe), instrument pipe, watch case pipe, injection needle and medical instrument pipe, etc.

Section shape classification

The steel grades and specifications of steel pipe products are extremely diverse, and their performance requirements are also various. All these shall be distinguished according to the change of user requirements or working conditions. Generally, steel pipe products are classified according to section shape, production method, pipe making material, connection mode, plating characteristics and application.

Steel pipes can be divided into round steel pipes and special-shaped steel pipes according to the shape of cross section.

Special shaped steel pipes refer to various steel pipes with non-circular circular section.

These mainly include:

- Square tube

- Rectangular pipe

- Elliptical tube

- Flat oval pipe

- Half round pipe

- Hexagonal tube

- Hexagonal inner tube

- Unequal hexagonal pipe

- Equilateral triangle pipe

- And So on ……

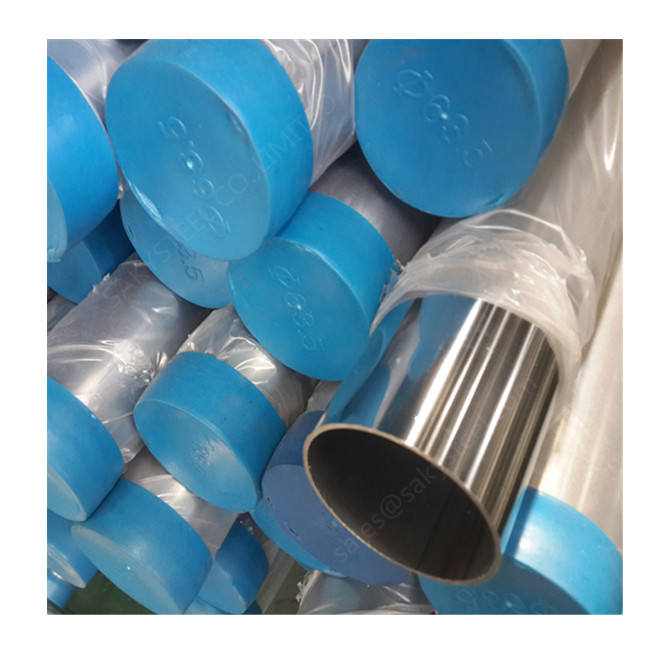

Steel Pipe Packing

The packaging method of steel pipes is very important to avoid deformation, scratches, pits and other problems during transportation.

Also as a professional Pipe Supplier and manufacturer,We provide reasonable packaging in various ways according to customers’ requirements and product properties. Packaging in an optimal way.