Welding and Metal Fabrication

May 23, 2023

Metal Frame Fabrication

May 23, 2023Aluminum Sheet Metal Fabrication: Crafting Precision and Durability

When it comes to constructing modern and sleek structures, aluminum sheet metal fabrication is a top choice for many industries. With its durable and lightweight properties, aluminum has become a go-to material for architects, engineers, and manufacturers worldwide.

When it comes to constructing modern and sleek structures, aluminum sheet metal fabrication is a top choice for many industries. With its durable and lightweight properties, aluminum has become a go-to material for architects, engineers, and manufacturers worldwide.

In this post, we’ll dive deeper into the world of aluminum sheet metal fabrication, exploring its unique properties, advantages, and the various applications it serves.

What is Aluminum Sheet Metal Fabrication?

It is the process of transforming raw aluminum sheets into various shapes and sizes through cutting, bending, and shaping. The process involves using specialized machinery, such as CNC routers, laser cutters, and hydraulic press brakes, to create precise and accurate parts and components.

One of the most significant advantages of it is its versatility. Aluminum sheets can be easily molded and shaped into any desired form, making it an ideal material for a wide range of industries.

Advantages of Aluminum Sheet Metal Fabrication

1. Lightweight and Durable

One of the most significant advantages of aluminum fabrication is its lightweight and durable properties. Aluminum has a high strength-to-weight ratio, making it an ideal material for various applications, including aerospace, automotive, and construction.

2. Corrosion-Resistant

Aluminum is naturally corrosion-resistant, making it an ideal material for outdoor applications. Unlike other metals, aluminum does not rust or corrode when exposed to moisture or harsh environments.

3. Easy to Fabricate

It is a relatively simple and straightforward process. The material can be easily cut, bent, and shaped into various forms, making it an ideal material for complex and intricate designs.

Applications of Aluminum Sheet Metal Fabrication

1. Architecture

It is a popular choice for architects and builders. The material’s lightweight and durable properties make it an ideal choice for constructing modern and sleek buildings. Aluminum’s corrosion-resistant properties also make it ideal for outdoor applications, such as roofing and cladding.

2. Automotive

It is commonly used in the automotive industry. The material’s lightweight properties make it an ideal choice for constructing cars, trucks, and other vehicles. Aluminum is also corrosion-resistant, making it ideal for outdoor applications.

3. Aerospace

It is widely used in the aerospace industry. The material’s lightweight properties make it an ideal choice for constructing aircraft and spacecraft. Aluminum’s corrosion-resistant properties also make it ideal for outdoor applications.

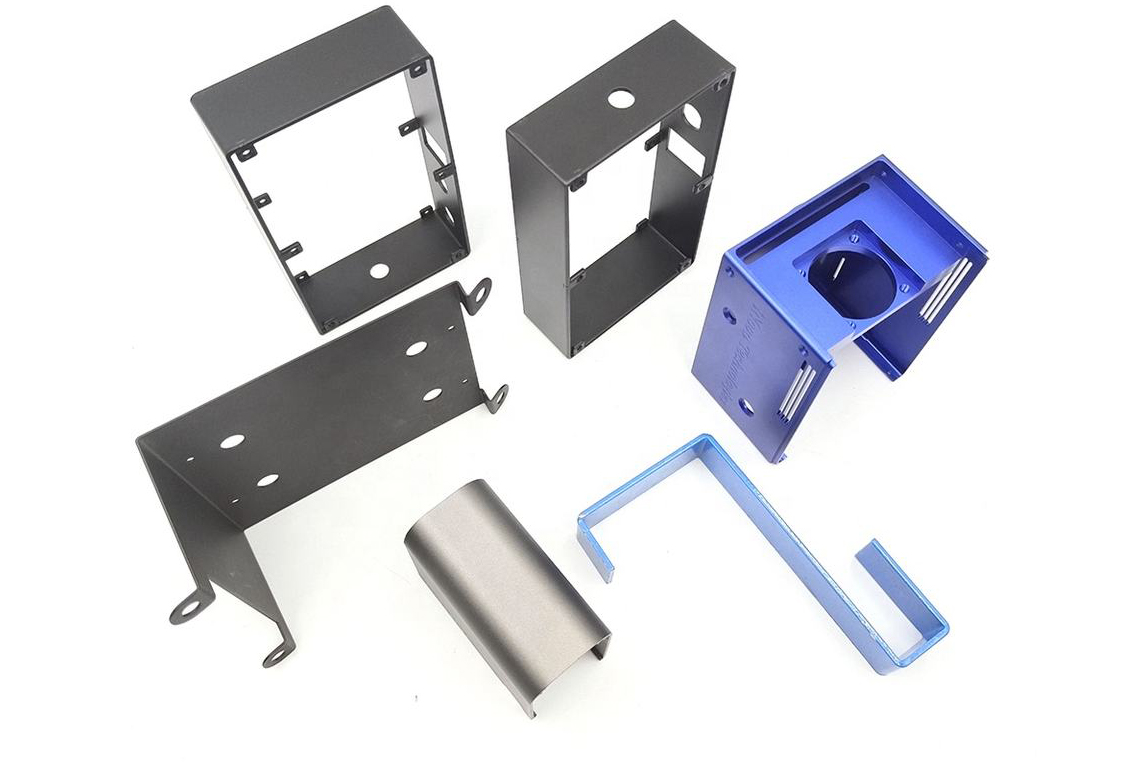

Custom Metal Fabrcation

| Product | ISO9001 Fabricator Custom Sheet Metal Fabrication Bending Stamped Metal Parts Laser Cutting Bending Sheet Metal Stamping Parts |

| Material | Stainless Steel, Carbon Steel(Q235), Aluminum(6061,6063, 5052), Copper, Brass and So on |

| Process | Bending, Stamping, Welding |

| Finish | Zinc Plating, Mirror Polished, Brush Polished, Paint, Anodic Oxidation, Powder Coated |

| Package | Plywood Box + Plywood Pallet, Plywood Box |

| OEM Service | Accept |

Conclusion

It is a popular and versatile process used in various industries worldwide. The material’s lightweight and durable properties make it an ideal choice for constructing modern and sleek structures, including buildings, vehicles, and aircraft. With its corrosion-resistant properties, aluminum is an ideal material for outdoor applications, making it a go-to choice for architects, engineers, and manufacturers worldwide.

In summary, aluminum fabrication offers precision, durability, and versatility, making it an excellent choice for various applications. Whether you’re working on a building, vehicle, or aircraft project, aluminum sheet metal fabrication can help you achieve your goals with ease.