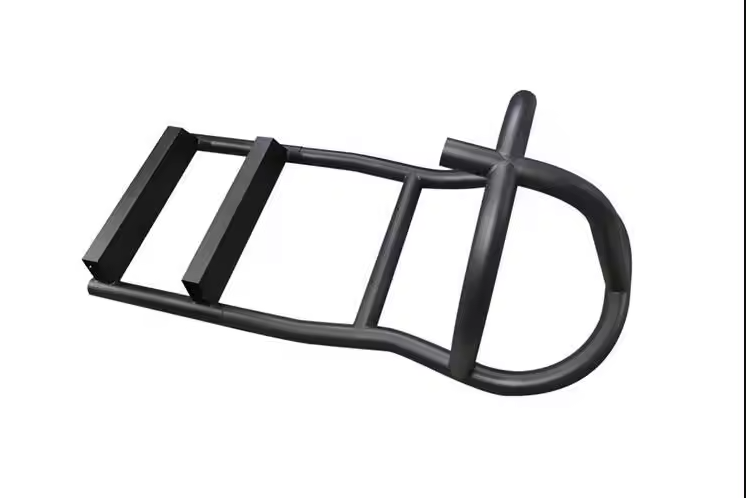

Automotive pipe bending

November 14, 2023

HVAC pipe bending

November 15, 2023The Significance and Applications of Plumbing Pipe Bending in Manufacturing

Plumbing pipe bending is a fundamental process in the manufacturing industry, playing a crucial role in the construction and installation of plumbing systems. This article aims to explore the significance of pipe bending, its technical considerations, advantages, and diverse applications in modern plumbing and construction projects.

1. Significance of Plumbing Pipe Bending:

It refers to the process of shaping pipes to fit the desired layout and configuration of a plumbing system. This technique offers several significant benefits that make it an essential component of various manufacturing processes:

1.1 Customization: Plumbing pipe bending allows manufacturers to tailor pipes to specific spatial requirements and design specifications. This customization ensures optimal fitment, minimizes material waste, and optimizes the functionality of the plumbing system.

1.2 Efficiency: By bending pipes instead of relying solely on straight sections, manufacturers can reduce the number of fittings and joints required in a plumbing system. This not only enhances the overall efficiency of installation but also decreases the likelihood of leaks or failures at connection points.

1.3 Space Optimization: In many construction projects, available space is limited, necessitating precise pipe bends to navigate around obstacles and maximize usable area. Plumbing pipe bending enables the creation of efficient pipe routing solutions, ensuring that plumbing infrastructure integrates seamlessly with the building’s layout.

2. Technical Considerations:

To achieve accurate and reliable plumbing pipe bending results, several technical considerations need to be taken into account:

2.1 Pipe Material: Different pipe materials, such as copper, PVC, or stainless steel, have varying properties that impact the bending process. Manufacturers must understand material characteristics and select appropriate tools and techniques to ensure successful pipe bending without compromising structural integrity.

2.2 Bending Methods: Depending on project requirements and pipe material, different bending methods can be employed, including manual bending tools, mechanical benders, or hydraulic pipe benders. Manufacturers should choose the most suitable method based on factors such as pipe diameter, wall thickness, and desired bending angle.

2.3 Precision and Accuracy: Achieving precise bends is crucial to maintain optimal flow rates within the plumbing system. Manufacturers must carefully calculate bend angles, radii, and distances between bends to ensure proper water flow, minimize pressure loss, and prevent obstructions.

3. Advantages of Plumbing Pipe Bending:

It offers various advantages that contribute to efficient plumbing system installation and enhanced performance:

3.1 Reduced Leak Potential: By minimizing the number of fittings and joints, plumbing pipe bending reduces potential leakage points in the system. This decreases the risk of water damage, promotes long-term system reliability, and lowers maintenance costs.

3.2 Improved Flow Efficiency: Smooth, accurately bent pipes allow for better fluid flow by eliminating sharp bends that can impede water movement. With optimized flow, plumbing systems can deliver water more efficiently, ensuring consistent pressure and distribution throughout the building.

3.3 Cost Savings: Plumbing pipe bending minimizes the need for additional fittings and connectors, saving both material costs and installation time. Moreover, reduced joint connections reduce the likelihood of leaks, resulting in lower repair and maintenance expenses over time.

4. Applications:

It finds widespread applications in various construction and plumbing projects:

4.1 Residential and Commercial Buildings: It is extensively used in residential and commercial buildings to create tailored layouts that efficiently transport water and handle drainage requirements.

4.2 Industrial Facilities: Manufacturing plants, warehouses, and other industrial facilities rely on plumbing pipe bending to design plumbing systems that meet specific operational needs, such as transporting chemicals, processing fluids, or managing wastewater.

4.3 HVAC Systems: Heating, ventilation, and air conditioning systems often require custom pipe bending to accommodate complex configurations and optimize airflow throughout a building.

4.4 Plumbing Repair and Retrofitting: It is also crucial in repair and retrofitting projects, where existing plumbing systems need modifications or replacement to meet updated building codes or accommodate building upgrades.

Conclusion:

It is indispensable in modern manufacturing processes, offering customization, efficiency, and space optimization benefits. By leveraging advanced bending techniques and considering critical technical aspects, manufacturers can create precise plumbing system layouts, improve flow efficiency, reduce leak potential, and achieve cost savings. From residential buildings to industrial facilities, the applications of plumbing pipe bending span numerous construction projects, ensuring efficient and reliable water distribution for a variety of purposes.