Sheet Metal Manufacturing

December 22, 2023

Basic Knowledge of Metal Plastic Deformation

February 13, 2024Enhancing Efficiency and Precision: Exploring Food and Beverage Pipe Bending

Efficient food and beverage processing relies on the seamless flow of liquids, gases, and materials through a well-designed pipe system. In this article, we delve into the world of food and beverage pipe bending, highlighting its crucial role in ensuring smooth operations. From a range of materials to various finishing options, this process offers flexibility, durability, and customization for the industry’s specific needs.

1. Material Options:

Food and beverage pipe bending involves working with a diverse array of materials to meet specific requirements. Stainless steel, known for its corrosion resistance and hygienic properties, is a popular choice due to its ability to withstand harsh environments. Aluminum and brass offer lightweight alternatives without compromising on strength. Additionally, carbon steel provides excellent durability for heavy-duty applications. The ability to choose from multiple materials allows for tailored solutions based on the particular demands of each project.

2. Finishing Choices:

The finishing of food and beverage pipes plays a crucial role in enhancing their durability, cleanliness, and appearance. Various surface finishes ensure that pipes are suitable for food handling, as well as compliant with industry regulations. Common finishes include powder coating, galvanization, brushing, polishing, anodizing, and chrome plating. Each finish option serves a specific purpose, such as providing an extra layer of protection against corrosion or improving the aesthetic appeal of the pipes. This versatility allows manufacturers to meet different hygiene standards and aesthetic preferences.

3. Food and Beverage Pipe Bending Precision Processes:

The pipe bending process requires a combination of expertise and advanced technologies to achieve accurate and consistent results. Laser cutting is employed to shape the raw materials with exceptional precision. Bending techniques, including cold bending and hot bending, transform straight pipes into curved or angled sections to fit specific layouts or systems. Welding ensures secure connections, adding strength and integrity to the pipe structure. These processes, performed with meticulous attention to detail, guarantee the highest level of quality and functionality.

4. Flexible Minimum Order Quantity (MOQ):

To meet the diverse needs of food and beverage businesses, reliable pipe bending manufacturers offer flexible minimum order quantities. With a low MOQ of just 50 units, companies can access custom pipe solutions without having to invest in large quantities upfront. This flexibility enables small and medium-sized enterprises to enhance their operational efficiency and adapt their infrastructure as per demand, optimizing costs and resources effectively.

5. Wide Range of Shapes:

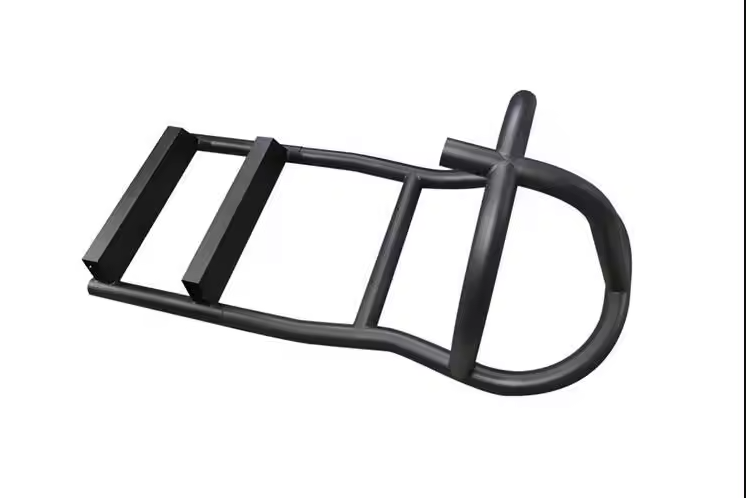

Food and beverage pipe bending accommodates various shapes to facilitate specific functions within processing systems. Industries often require round pipes, square tubes, flat iron, angle steel, channel steel, and special-shaped configurations to accommodate different flow rates, pressures, and structural requirements. The ability to customize the shape of the pipes allows for seamless integration into existing setups or the creation of tailored solutions for new installations, ensuring optimum performance and maximizing space utilization.

Food and Beverage Pipe Bending Conclusion:

The food and beverage industry relies on efficient piping systems to maintain the smooth flow of essential liquids and materials. Pipe bending offers a comprehensive range of materials, finishes, and shapes to meet specific requirements and support optimal functionality. From stainless steel to aluminum and carbon steel, each material brings its unique advantages to the table. Combined with precise processes and flexible MOQs, the customized solutions provided by pipe bending manufacturers ensure enhanced efficiency, durability, and compliance within the food and beverage sector.