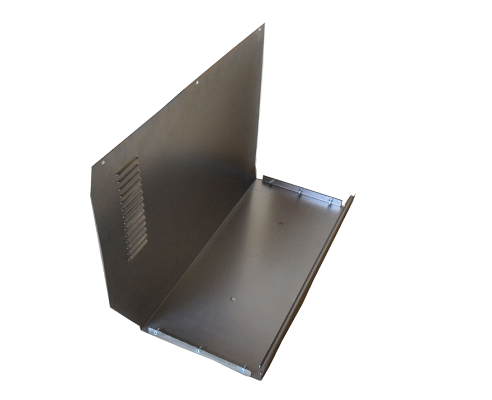

Galvanize sheet metal fabrication

December 20, 2019

Custom Sheet Metal

March 13, 2020Custom metal stamping service

We use different type of stamping machine (cover from hand to precision punch) to offer custom metal stamping service. According to customer’s order quantity,we offer the most cost-effective way to your project, we can use laser cutting,Single-shot or continuous progressive die automated production.

Production Ability

Processing range: blanking, cutting, forming, rolling, drawing, bending, flaring, shrink tube, drilling, tapping, spot welding nuts or screws.

Pressing Capacity: 6.3-600 tons

Surface treatment: Plating, Galvanization, Anodized and Powder coating

* Plating: Zinc, nickel, chromium, silver, etc.

* Anodized and Electrophoresis

* Paint and Powder

* Vibration deburring, polishing and chemical treatment

* Screen printing, color printing and laser engraving.

Materials:Steel, Stainless Steel, Brass, Copper, Aluminum, etc

Tolerance:0.02mm

Quality system certification: ISO 9001-2000

Lead Time:5~25days

QC System:100% inspection before shipment.

Packagings:1) Standard package,

2) Pallet or container,

3) As per customized specifications.

Payment Terms:

T/T , L/C , Paypal

Shipment Terms:

1) 0-100kg: express&air freight priority,

2) >100kg: sea freight priority,

3) As per customized specifications.

FAQ about metal stamping

1.Do you inspect the raw material?

Each batch of materials is carefully tested by inspector on appearance, raw material defects, wire drawing size etc. and the testing result is filed in computer. All the checmical composition as well as material warranty documents of raw materials is spot checked.

2.Do you inspect the goods during the production?

Inspector test each process according to the order and the corresponding product standard, each process has corresponding operation instruction. All the test result is filed in the corresponding computer daily. Mechanical properties are filed in paper documents.

3.How do you control each batch goods?

Statistician keep recording and filing all batch of the incoming products, noted with contract No., model, size, quantity, weight, surface color etc.

4.Will you ship the unqualified goods?

Concerning to abnormal occurrence or unqualified products: Unqualified products processing sheet is reported to QC dept. by inspector. The reworking will be done after QC workers come up with solutions and suggestions.

5.How do you manage your files?

All the documents or customer orders is given out by designated personnel. The drawings and exterior documents are given out and recorded by QC department.