CNC Laser Cutting Service

February 14, 2022

Aluminum Extrusion Cabinet

February 23, 2022V Shape Stamping Clips

Custom-made V Shape Stamping Clips was made accoording to customer’s drawing.

Material: carbon steel

Size : 50mm

Thickness: 1.5mm

Weight : 0.137 kg

Surface treatment : Black Powder Coating

Stamping Clips Manufacturer

We are metal stamping parts and other sheet metal parts manufacturer. Our main production modes are designing and proofing based on drawings, concepts and samples provided by customers. We provide samples for customers for review, verification and confirmation and then put into production

We have many sets of stamping machine and with the ability of many kinds of surface finish treatment. If you have any new project which need customized clips.Please send us drawing.

Our Technicians will design the best production pross by our super quality production dies,which enable that you can get a super quality products with low cost. That’s why many customer stick to us.

V Shape Stamping Clips process

As a professional metal parts manufacturer, you will know that the quality of metal stamping parts are influence by material, Dies,Machine.

The material we buy are from domestic famous maker.We can offer mill sheet for each lots of production.

The most important factor for the quality is the dies.The dies will be designed differently according to different quantity.

Stamping Dies

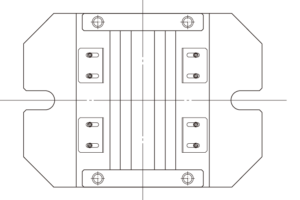

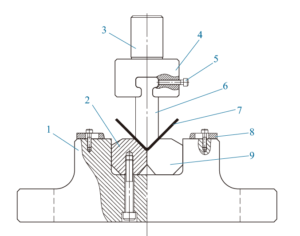

As shown in above pictures, it is a general V-shaped bending die. The bending die of the die adopts a split structure (the bending die is divided into left and right)

The right two pieces) can only replace the bending punch 6 in a pair of molds to realize the bending of various angles. The die is not topped due to bending

Therefore, it is more reasonable to use this die for parts with low requirements for bending accuracy.

The structure can be bent at four different angles (120 °, 90 °, 80 ° and 60 °). For example, when bending 120 °, it is more flexible.

Replace the bending punch 6 and turn the bending die 2 and bending die 9 to the position of 120 °. The lower die base 1 adopts an integral structure, which can well prevent the outward movement of the die 2 and die 9 during bending.