Aluminum Enclosure Fabrication

April 19, 2022

Classification Of Metal Materials

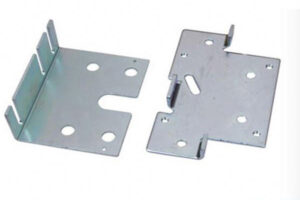

June 10, 2022Custom Sheet Metal Bending

We are professional manufacturer engaged in the research, development, production, sale and service of Custom Sheet Metal Bending, with IS09001 certification.

We are professional manufacturer engaged in the research, development, production, sale and service of Custom Sheet Metal Bending, with IS09001 certification.

Dedicated to strict quality control and thoughtful customer service, our experienced staff are always available to meet your requirements and ensure full customer satisfaction.

Our company has introduced a series of advanced equipment including laser cutting machine, turret punch press, CNC bending machine, CO2 gas shielded welding, TIG welding, spot welding, CNC engraving and milling machine.

Whether selecting a current product from our catalog or seeking engineering assistance for your application, our customer service center is available to your sourcing requirements.

What is Sheet Metal Bending

Sheet metal bending refers to, the bending and forming of sheet metal are carried out on the bending machine. Place the workpiece to be formed on the bending machine, lift the brake shoe with the lifting lever, slide the workpiece to the appropriate position, and then lower the brake shoe to the workpiece to be formed, so as to realize the metal bending and forming by applying force to the bending lever on the bending machine.

The minimum bending radius is a function of the ductility and thickness of the formed metal. For aluminum plate, the bending radius of metal is greater than the thickness of plate. During bending, due to certain rebound, the angle of metal bending is slightly larger than the required angle. The bending of sheet metal is carried out in the metal processing workshop.

Custom Sheet Metal Fabrication

| Name | Detail | Optional |

| Material | GB, JIS, ASTM, DIN, AISI.EN,AS. | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, Titanium Alloy, Nylon, Acrylic, UHMWPE, PVC etc. |

| Shape | Plate, Tube, Rod. | |

| Processings | Accept | Laser Cutting, Precision Stamping, CNC Bending, CNC Milling, CNC Turning, Threading, Riveting, Drilling, CNC Punching, Die Casting, Laser Welding etc |

| Surface Treatment | Accept | Brushing, Polishing, Vacuum Plating, Anodizing, Powder Coating, Zinc Plating, Chrome Plating, Nickel Plating, Tin plating etc |

| logo | Accept | Silk print, Laser marking, UV print, Multicolor pad printing. |

| Size | 160*200*150mm. | Accept custom size. |

| Color | RAL , Pantone, RGB, CMYK. | White, black,silver, red, grey etc |

| Software | CAD, Solidworks, CATIA, UG, PRO-E. Inventor, AI | |

| Drawing format | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI,PDF, JPG, Draft. | |

| Sample lead time | No surface treatment, 1-3 workdays. Require surface treatment, 3-5 workdays. |

|

| Pricing Term | FOB, CIF, DDP etc | |

| Port of Loading | Shanghai or Ningbo | |

| Payment term | TT (50% in advance as deposit, balance before delivery) , or to be confirmed | |

OEM Service

We use 3D SolidWorks to make your product simulation which helps us to identify how this sheet metal design will work.

Besides, with this software,we can correct any error before your products fabricated to save time and cost.

Our Design&Manufacturing Advantages

- Experience in multiple industries

- Provide suggestions to improve drawing

- Metal processing knowhow

- Excellent Welding Skill