Coil Pipe Bending

November 10, 2023

Tight Radius Bending

November 10, 2023The Art of Multi-Radius Bending in Manufacturing

In the world of pipe and tube bending, achieving complex and aesthetically pleasing shapes often requires advanced techniques. One such technique is multi-radius bending, which allows manufacturers to create intricate bends with multiple radii. This article aims to explore the concept of multi-radius bending, its applications, benefits, and considerations for successful implementation.

1. Understanding Multi-Radius Bending:

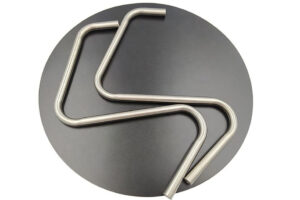

Multi-radius bending involves the precise manipulation of pipes or tubes to create bends with varying radii along their length. Unlike traditional bending methods that rely on a single radius, multi-radius bending enables manufacturers to achieve more complex shapes, including S-bends, compound curves, and other intricate designs. This technique finds applications in industries such as automotive, architecture, aerospace, and furniture manufacturing.

2. Advantages:

a. Design Flexibility: By incorporating multiple radii within a single bend, manufacturers can create visually appealing and structurally efficient components. This flexibility enhances design possibilities and allows for the realization of unique and innovative shapes.

b. Improved Functionality: Multi-radius bent pipes and tubes offer enhanced functionality, particularly when dealing with space constraints or specific flow requirements. Such bends ensure optimal flow characteristics and minimize pressure drop, making them ideal for applications involving fluid or gas transportation.

c. Aesthetics: Multi-radius bends can add an artistic touch to architectural structures, furniture designs, and decorative elements. They allow for the creation of flowing, organic shapes that are visually striking and distinctive.

3. Considerations for Successful Multi-Radius Bending:

a. Material Selection: Different materials exhibit varying levels of flexibility and resilience during bending. Understanding the material’s behavior and choosing the appropriate one for the application is crucial to ensure successful multi-radius bending.

b. Tooling and Equipment: Specialized bending machines equipped with multiple forming dies or mandrels designed for them are essential for achieving accurate and consistent results. Ensuring appropriate tooling selection based on the desired bend radii is crucial.

c. Process Planning and Simulation: Thorough process planning, including simulation software, can help predict and visualize the outcome of it before manufacturing begins. This aids in identifying potential challenges and optimizing the bending parameters.

d. Quality Control and Inspection: Implementing rigorous quality control measures throughout the multi-radius bending process ensures dimensional accuracy, surface finish, and integrity of the bent components. Non-destructive testing methods, such as visual inspection or ultrasonic examination, can be employed to detect any defects or imperfections.

4. Applications:

a. Architectural Structures: Multi-radius bends find extensive use in architectural designs, allowing for the creation of unique building facades, curved staircases, and artistic installations.

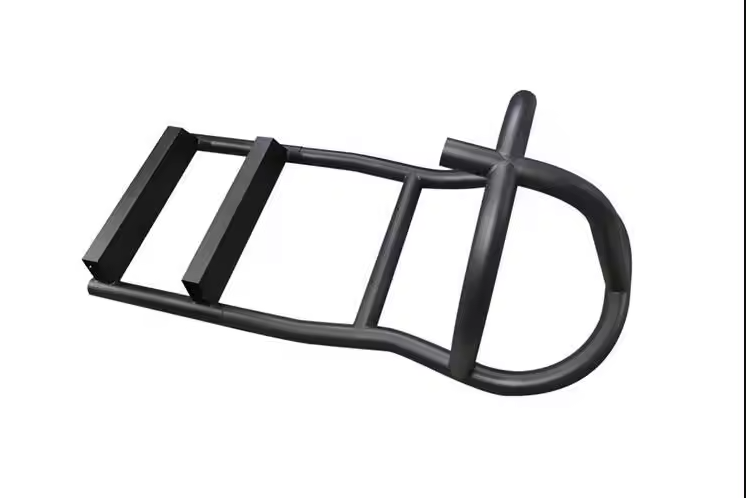

b. Automotive Industry: From exhaust systems and roll cages to suspension components, multi-radius bending plays a crucial role in manufacturing various automotive parts that require precise shaping and intricate design.

c. Furniture and Interior Design: Multi-radius bending enables the production of curved furniture pieces, handrails, and other decorative elements that add visual appeal and elegance to interior spaces.

d. Aerospace Industry: Aerospace applications require complex tube and pipe configurations with tight tolerances. It allows for the production of aircraft frames, fuel delivery systems, and hydraulic tubing.

Conclusion:

It is an advanced manufacturing technique that empowers manufacturers to create complex and visually striking bends with varying radii. By expanding design possibilities, offering improved functionality, and enhancing aesthetics, this technique finds applications in diverse industries. Successful implementation of multi-radius bending requires careful consideration of materials, appropriate tooling and equipment, thorough process planning, and stringent quality control measures. Embracing this artful bending technique can unlock new possibilities for manufacturers and enable the production of highly customized and innovative components.