Flower Pattern Laser Cutting

March 31, 2022

Metal Laser Cutting Service

April 19, 2022Precision Sheet Metal Fabrication

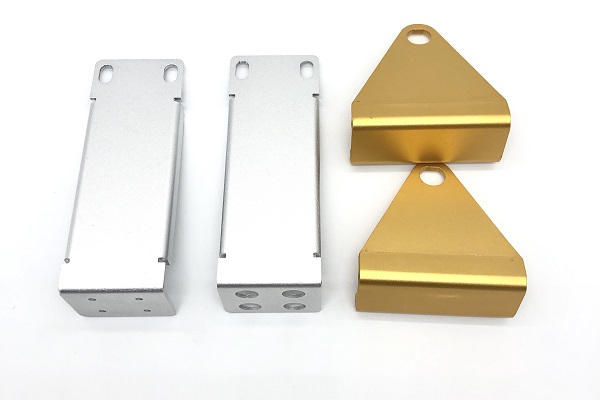

We not only supplying Precision Sheet Metal Fabrication products to our customers , but also trying to build more values to our customers’ business by introducing suitable solution or technology to our customers with compromising parts’ function, technologies’ advantage, realization feasibility, cost control and quality reliability.

Precision Sheet Metal Fabrication Manufacturer

|

Custom Precision Sheet Metal Fabrication Parts |

|

| Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

| Material | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, etc. |

| Processing | Laser Cutting, Precision Stamping, Bending, CNC Punching, Threading, Riveting, Drilling, Welding etc |

| Surface Treatment | Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen printing, Sandblast, etc |

| Tolerance | +/-0.2mm, 100% QC quality inspection before delivery, can provide quality inspection form |

| Logo | Silk print, Laser marking. |

| Size | Accept custom size. |

| Color | White, black,silver, red, grey, Pantone and RAL, etc |

| Drawing format | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI,PDF, JPG, Draft. |

| Sample lead time |

No surface treatment, 1-3 workdays. Require surface treatment, 3-5 workdays. |

| Pricing Term | EXW, FOB, CIF, etc |

| Payment term | Sample: 100% payment before production

Mass production: (50% in advance as deposit, balance before delivery) |

| Certificate | ISO9001:2015/SGS/TUV/RoHS |

| Packing | By carton or as your request |

1.Name:metal stamping kit for jewelry making custom metal parts aluminum fabric waterjet cutting service sheet metal bending

2. We are OEM manufacurer acc. to customer’s drawings and samples.

3. Standard: Acc.to customer’s requirements.

Industry Experience

Many years of industry experience . Throughtout these time , we have set up a robust quality

assurance system to ensure quality standard . We understand the importance of quality assurance , well defined lead time , strong after sale service and timely customer communication .

Production Capability

We have two assembly lines and four production lines . We have equipments for lathing , punching , drilling ,milling , laser cutting , bending , welding , grinding and CNC processing all under one roof .

Skills

We have a team of five engineers and two R&D personnel . With this setup and the help of advance

3D modelling software , we can make product out of customer ‘ s drawings , samples or as simple as just idea .

Certification/Patents

We are ISO9001 . 2015 certified . We have a range of petents from invention , design to practicality .

Workforce

We have over 150 employees both in the workshop and office that can cater to a large influx of workflow .

Additonal Services

We offer one-stop service for any of your new projects.Besides of Aluminum extrusion,We also can save your time for other relative service ,such as