Welded pipe bending

November 6, 2023

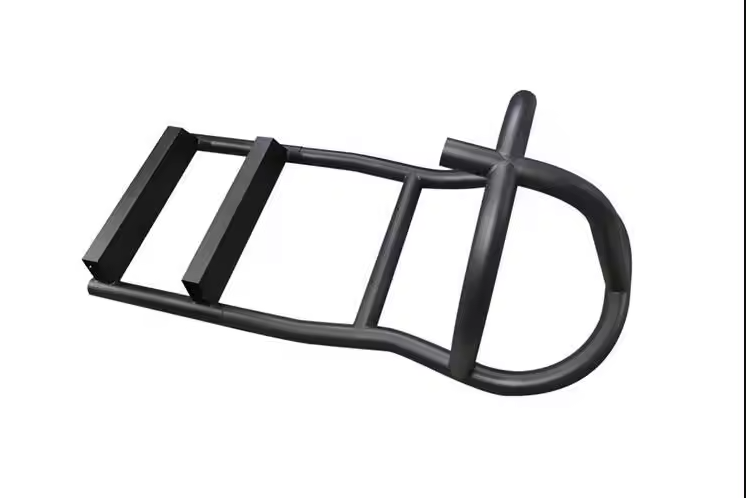

Rectangular Tube Bending

November 8, 2023Square Tube Bending: A Comprehensive Guide for Manufacturers

It is a specialized manufacturing process that involves reshaping square tubes into desired configurations. This technique finds extensive use in a wide range of industries, including construction, automotive, aerospace, and furniture. As a manufacturer specializing in square tube bending, it is crucial to have a thorough understanding of the process, materials, equipment, and applications involved. This article aims to provide a comprehensive guide for manufacturers involved in square tube bending, highlighting key considerations and best practices.

1. Understanding Square Tube Bending:

It involves applying external forces to reshape square tubes into various shapes, including curves, angles, arcs, and complex geometries. The process requires precision and skilled craftsmanship to ensure the desired outcome. There are two primary methods used in tube bending: rotary draw bending and roll bending. Each method has its advantages and considerations, depending on the specific requirements of the project.

2. Materials:

The choice of materials plays a significant role in the success of square tube bending processes. Commonly used materials include:

a. Metals:

– Mild Steel: Known for its versatility, strength, and cost-effectiveness.

– Stainless Steel: Offers excellent corrosion resistance and durability.

– Aluminum: Lightweight and highly malleable, ideal for applications requiring weight reduction without compromising strength.

– Copper: Known for its superior electrical conductivity, making it suitable for electrical and plumbing applications.

– Titanium: An excellent choice for industries demanding high strength-to-weight ratios, such as aerospace.

b. Plastics:

– PVC: Durable, lightweight, and resistant to chemicals, making it popular in plumbing and electrical applications.

– ABS: Offers good impact resistance and is commonly used in automotive components and consumer goods.

– Nylon: Known for its excellent mechanical properties, including high temperature resistance, toughness, and wear resistance.

– HDPE: Resistant to chemicals, moisture, and impact, making it suitable for applications in agriculture, packaging, and construction.

3. Applications:

Square tube bending finds extensive applications across various industries, including:

a. Construction: Square tubes are commonly used in architectural structures, railing systems, and framework for buildings and bridges.

b. Automotive: It is utilized for manufacturing exhaust systems, roll cages, chassis components, and suspension parts.

c. Furniture: Square tubes are employed in the production of stylish and sturdy furniture, including tables, chairs, and shelves.

d. Aerospace: Critical aircraft components, such as wing struts and structural frames, often require precision bending processes.

e. Industrial Machinery: Square tubes are crucial for manufacturing conveyor systems, equipment frames, and safety barriers.

4. Best Practices for Square Tube Bending:

To ensure successful square tube bending processes, consider the following best practices:

a. Material Selection: Choose materials based on project requirements, considering factors such as strength, durability, corrosion resistance, and weight.

b. Tooling and Equipment: Ensure the use of high-quality tooling and machinery suitable for tube bending processes to achieve precise and consistent results.

c. Precision Measurements: Accurate measurements are vital for achieving the desired shapes and angles during the bending process. Utilize advanced measurement techniques and equipment.

d. Quality Assurance: Implement stringent quality control measures to ensure that the finished products meet the required specifications and standards.

e. Skilled Workforce: Employ highly skilled and trained operators proficient in square tube bending techniques to ensure optimal results.

Conclusion:

As a manufacturer specializing in tube bending, it is essential to have a comprehensive understanding of the process, materials, and applications involved. By considering the factors discussed in this article, manufacturers can ensure the successful execution of square tube bending projects across various industries. The ability to deliver high-quality, precisely bent square tubes is crucial for meeting customer demands and establishing a strong reputation in the market.