Aluminum pipe bending

November 1, 2023

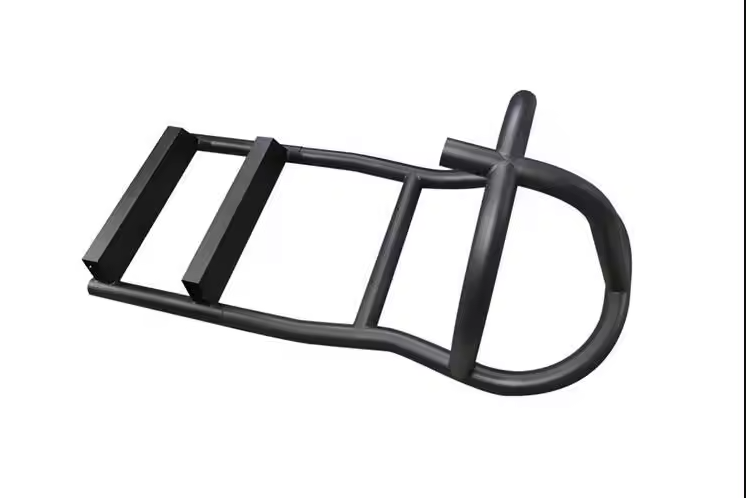

Steel pipe bending

November 3, 2023The Art and Science of Copper Pipe Bending

Copper pipes are widely used in plumbing and HVAC systems due to their excellent thermal conductivity, durability, and corrosion resistance. One critical skill required for working with copper pipes is bending them accurately and efficiently. In this article, we will explore the techniques, tools, and considerations involved in proper copper pipe bending.

Copper pipes are widely used in plumbing and HVAC systems due to their excellent thermal conductivity, durability, and corrosion resistance. One critical skill required for working with copper pipes is bending them accurately and efficiently. In this article, we will explore the techniques, tools, and considerations involved in proper copper pipe bending.

1. Understanding Copper Pipes:

Before diving into the techniques of bending copper pipes, it’s essential to understand the properties of copper. Copper pipes come in different grades, such as Type M, L, and K, each with specific wall thicknesses suitable for different applications. Familiarize yourself with the type of copper pipe you are working with to ensure correct bending procedures.

2. Tools Required for Copper Pipe Bending:

To bend copper pipes effectively, you will need a few essential tools:

a) Pipe Bender: A pipe bender is designed specifically for bending copper pipes without causing any damage or kinks. Manual and hydraulic pipe benders are available, enabling precise and smooth bends at various angles.

b) Measuring Tape: Accurate measurements are crucial for achieving desired bends. Use a measuring tape to mark the desired bend point and determine the length of pipe required.

c) Deburring Tool: Before bending, use a deburring tool to remove any sharp edges or burrs from the cut end. This step ensures a clean and smooth bending process.

d) Pipe Cutter: In cases where the pipe needs to be cut before bending, a pipe cutter is necessary. This tool ensures clean and accurate cuts without causing deformation.

3. Techniques for Copper Pipe Bending:

There are two primary methods for bending copper pipes:

a) Freehand Bending: Freehand bending involves using a pipe bender and manually bending the pipe to achieve the desired angle. This method is suitable for simple bends with larger radius requirements.

b) Spring Bending: For more complex bends or tight-radius curves, spring bending is the preferred technique. This method involves inserting a spring inside the pipe, allowing it to retain its shape while bending. Springs of various sizes and shapes are available to accommodate different bending requirements.

4. Considerations for Copper Pipe Bending:

When bending pipes, some critical considerations include:

a) Pipe Supports: Properly secure the pipe during bending to prevent any movement or vibrations that may impact the quality of the bend.

b) Temperature: Copper pipes become more pliable when heated. If necessary, apply gentle heat with a propane torch or electric heat gun to make bending easier. Be cautious not to overheat the pipe, as this can lead to discoloration or weakening of the copper.

c) Bend Radius: Copper pipes have a minimum recommended bend radius specified by the manufacturer. Exceeding this radius can cause damage or structural issues. Always refer to the manufacturer’s guidelines for acceptable bend radii.

5. Testing and Inspection:

After bending the copper pipe, it is crucial to inspect the bend for any deformities, kinks, or signs of stress. Inadequate bends can impact water flow, cause leaks, or reduce system efficiency. Take the time to review the bend carefully before installation.

Conclusion:

Copper pipe bending is a skill that requires precision and attention to detail. By following the appropriate techniques and using the right tools, you can achieve accurate bends without compromising the integrity of the pipe. Remember to refer to manufacturer guidelines, maintain proper support, and inspect bends thoroughly to ensure optimal performance in plumbing and HVAC systems.