Copper Pipe Bending

November 3, 2023

Galvanized pipe bending

November 4, 2023Excelling in Steel Pipe Bending: The Art of Precision Manufacturing

As a manufacturer specializing in pipe bending, we understand the importance of precision and quality in this niche industry. Steel pipes are widely used in various sectors, including construction, infrastructure, oil and gas, and manufacturing. In this article, we will delve into the art and science of steel pipe bending, discussing the techniques, equipment, and expertise required to excel in this field.

1. Understanding Steel Pipes:

Steel pipes are renowned for their high strength, durability, and versatility. They are manufactured using different grades of steel, such as carbon steel, stainless steel, and alloy steel, each offering unique characteristics suitable for specific applications. Before delving into the bending process, it is crucial to have a thorough understanding of the properties and limitations of the steel being used.

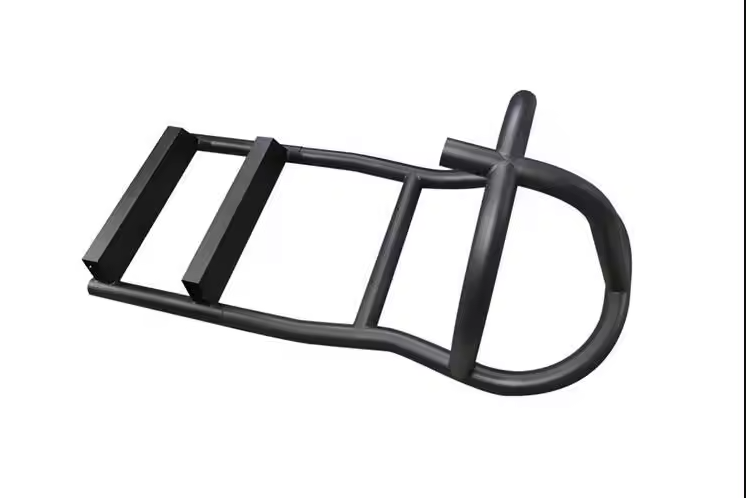

2. Equipment and Tools of Steel pipe bending:

To achieve precise steel pipe bends, manufacturers rely on specialized equipment and tools, including:

a) Pipe Bending Machines: Advanced hydraulic or CNC-controlled pipe bending machines play a pivotal role in achieving accurate and consistent bends. These machines can bend pipes of various diameters and wall thicknesses, ensuring repeatability and efficiency in production.

b) Mandrels: Mandrels are used during the bending process to maintain the shape and prevent distortion or flattening of the pipe. They provide internal support, especially when dealing with larger diameter or thin-walled pipes.

c) Measuring Instruments: Accurate measurements are crucial for achieving desired bend angles, radii, and lengths. Manufacturers use various measuring instruments, such as calipers, tape measures, and angle finders, to ensure precision during the bending process.

3. Techniques for Steel Pipe Bending:

It is a complex process that requires technical expertise and careful execution. Here are some commonly employed techniques:

a) Hot Induction Bending: This method involves heating the steel pipe to a specific temperature using an induction heating coil, which makes it more pliable and easier to bend. The heated pipe is then placed on a bending machine and bent to the desired angle using hydraulic pressure. Hot induction bending is ideal for large-diameter or thick-walled pipes.

b) Cold Bending: Cold bending is performed without pre-heating the steel pipe. It is commonly used for smaller diameter pipes or those with thicker walls. This technique requires precision control of the bending machine to ensure the integrity of the pipe is maintained.

4. Quality Control and Inspection:

Manufacturers of steel pipe bending understand the significance of stringent quality control measures. To ensure the highest standards are met, the following aspects should be considered:

a) Visual Inspection: Upon completion of the bending process, each pipe should undergo a visual inspection to check for any deformities, cracks, or imperfections. Any anomalies should be addressed before the pipe moves forward in the production process.

b) Non-Destructive Testing (NDT): NDT techniques, such as ultrasonic testing or dye penetrant inspection, can be employed to detect internal or surface defects that may compromise the integrity of the pipe. NDT helps identify potential issues early on, allowing for necessary corrective actions.

5. Compliance with Standards and Specifications:

Manufacturers of steel pipe bending must adhere to relevant industry standards and specifications. These may include ASTM, ASME, API, or ISO standards, depending on the application and end-use requirements. Following these guidelines ensures that the bent steel pipes meet the required parameters of strength, dimensional accuracy, and surface finish.

Conclusion:

Being a manufacturer specializing in steel pipe bending is a testament to the precision, expertise, and commitment to quality demanded by the industry. By leveraging advanced equipment, employing appropriate bending techniques, and adhering to strict quality control measures, manufacturers can deliver steel pipes that meet the highest standards. With a focus on precision and dedication to customer satisfaction, success in the steel pipe bending industry is within reach.