Steel pipe bending

November 3, 2023

Seamless Pipe Bending

November 4, 2023Galvanized Pipe Bending Techniques for Manufacturers

Galvanized pipes play a crucial role in various industries, offering excellent corrosion resistance and durability. As a manufacturer of pipes bending, it is essential to ensure accurate and precise bending to meet the specific requirements of your customers. This article aims to provide valuable insights into the techniques, tools, and considerations involved in galvanized pipe bending, enabling manufacturers to produce high-quality products efficiently.

1: Understanding Galvanized Pipes

1.1 Galvanizing Process:

– Explanation of the galvanizing process, where zinc coating is applied to the surface of steel pipes.

– Discuss the benefits of galvanized pipes, such as corrosion resistance and longevity.

1.2 Types of Galvanized Pipes:

– Briefly explain the different types of galvanized pipes available, including hot-dip galvanized pipes and electro-galvanized pipes.

2: Tools and Equipment for Galvanized Pipe Bending

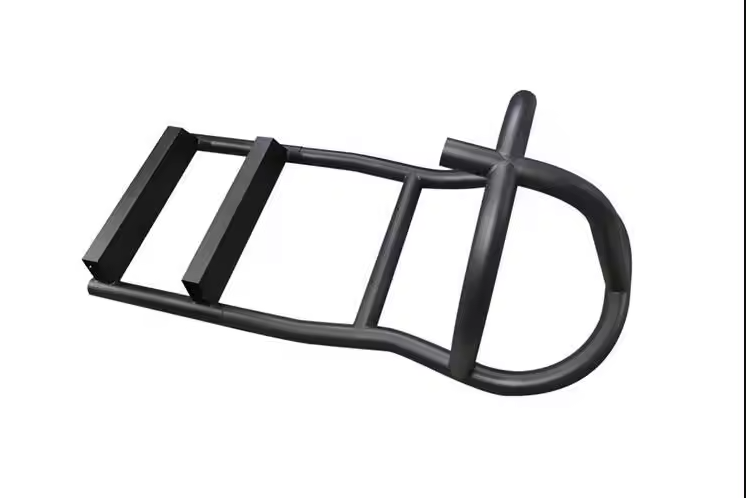

2.1 Pipe Benders:

– Discuss the importance of using specialized pipe bending equipment designed for galvanized pipes.

– Highlight the different types of pipe benders available, such as manual benders, hydraulic benders, and CNC bending machines.

– Provide recommendations on selecting the appropriate bender based on production volume and bending requirements.

2.2 Support Tools:

– Discuss the necessary support tools, including measuring tools (tape measure, calipers), marking tools (scribe, chalk), and cutting tools (hacksaw, tube cutter).

– Emphasize the use of deburring tools to remove sharp edges after cutting.

3: Techniques for Galvanized Pipe Bending

3.1 Pre-Bending Considerations:

– Explain the significance of proper planning, measurements, and calculations before initiating the bending process.

– Highlight the importance of considering bend radius, limitations, and angles as per customer specifications.

3.2 Cold Bending:

– Discuss the technique of cold bending, which involves bending pipes at ambient temperatures using mechanical force.

– Explain the limitations and desired outcomes of cold bending for galvanized pipes.

3.3 Hot Induction Bending:

– Explore the hot induction bending process, which uses localized heating to achieve precise bends.

– Discuss the benefits of hot induction bending, including reduced deformation and enhanced control over wall thinning.

4: Safety Considerations

4.1 Personal Protective Equipment (PPE):

– Emphasize the importance of wearing appropriate PPE, such as safety goggles, gloves, and ear protection, to ensure worker safety during the bending process.

4.2 Handling and Storage:

– Provide guidelines on proper handling and storage of galvanized pipes, considering their weight, length, and vulnerability to damage.

Conclusion:

Bending galvanized pipes requires careful consideration of techniques, tools, and safety measures to ensure optimal results. As a metal fabrication manufacturer of galvanized pipes, mastering these bending techniques will enable you to deliver high-quality products that meet customer requirements. By investing in the right equipment and following best practices, you can enhance your manufacturing efficiency and reputation in the industry.