Metal cutting

October 11, 2023

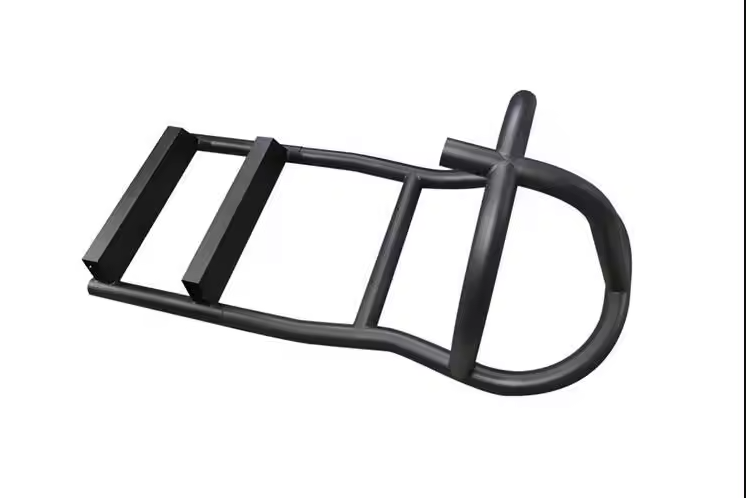

Cold Pipe Bending

October 23, 2023Hot pipe bending

Hot pipe bending is a specialized metal forming process that involves heating a pipe to a high temperature and then bending it into a desired shape. This process is often used in industrial applications where precise and complex curves are required, such as in pipelines, exhaust systems, and structural supports.

Hot pipe bending is a specialized metal forming process that involves heating a pipe to a high temperature and then bending it into a desired shape. This process is often used in industrial applications where precise and complex curves are required, such as in pipelines, exhaust systems, and structural supports.

The hot pipe bending process begins by heating the pipe to a temperature above its recrystallization point. This temperature varies depending on the type of material being used, but typically ranges from 800 to 1200 degrees Fahrenheit. Once the pipe has reached the desired temperature, it is placed in a bending machine and manipulated into the desired shape.

One of the key benefits of hot pipe bending is that it allows for precise and complex bends that are difficult or impossible to achieve with other methods. The high temperature softens the material, making it more malleable and easier to bend without cracking or deforming. This allows for tighter radiuses and more intricate shapes than can be achieved with cold bending or other forming processes.

Hot pipe bending also has the advantage of producing a smoother and more consistent curve than other methods. Because the material is heated uniformly, there are fewer stress points or deformations in the pipe, resulting in a more uniform and symmetrical curve. This can be especially important in applications where the pipe will be subject to high pressures or stress, as it can improve the integrity and strength of the pipe.

Custom Pipe Bending Companies in China offer hot pipe bending services for a variety of applications and industries. They have specialized equipment and expertise to handle a wide range of pipe sizes, shapes, and materials, including stainless steel, carbon steel, and aluminum. They can also provide custom designs and prototypes to meet specific application requirements.

When selecting a hot pipe bending manufacturer, it is important to consider factors such as experience, quality control, and pricing. A reputable manufacturer will have a proven track record of producing high-quality parts with tight tolerances and consistent performance. They will also use state-of-the-art equipment and techniques to ensure that each part meets or exceeds customer expectations.

In conclusion, hot pipe bending is a specialized and effective metal forming process that offers numerous benefits over other methods. By heating the material to a high temperature, it allows for precise and complex curves that are difficult to achieve with other methods, resulting in a smoother and more consistent shape. Custom Pipe Bending Companies in China offer this service with a focus on high-quality, customization, competitive pricing, fast turnaround times, and superior customer service. By working with a trusted manufacturer, customers can ensure that they are getting the right parts for their needs.