Custom Tube Bending

October 10, 2023

Metal cutting

October 11, 2023The Art of Mandrel Pipe Bending: Techniques, Equipment, and Applications

Mandrel pipe bending is a widely used technique in various industries, offering precise and efficient results. This article explores the process of mandrel bending, including its techniques, equipment, and applications. Whether you’re a professional in the field or an enthusiast seeking more knowledge, this article will provide valuable insights into the art of pipe bending.

1. Understanding Mandrel Pipe Bending:

It is a process used to curve pipes without deformation or wrinkling. The term “mandrel” refers to a flexible object inserted into the pipe to prevent it from collapsing or losing its shape during the bending process. By using a mandrel, the pipe maintains its internal diameter and shape, ensuring optimal functionality.

2. Mandrel Bending Techniques:

There are several techniques employed in mandrel bending, depending on the required bend radius and the material properties. Let’s explore two commonly used techniques:

a. Rotary Draw Bending:

This technique involves clamping one end of the pipe while rotating it around a bend die. A mandrel is inserted into the pipe to maintain its shape. As the pipe rotates, pressure is applied to bend it to the desired angle. Rotary draw bending is suitable for tight radius bends and precise, complex shapes.

b. Compression Bending:

In compression bending, the pipe is bent using hydraulic or mechanical force. A segmented mandrel is placed inside the pipe, and pressure is applied to the outside of the pipe using a bending machine. This technique is ideal for larger radius bends and heavy-wall pipes.

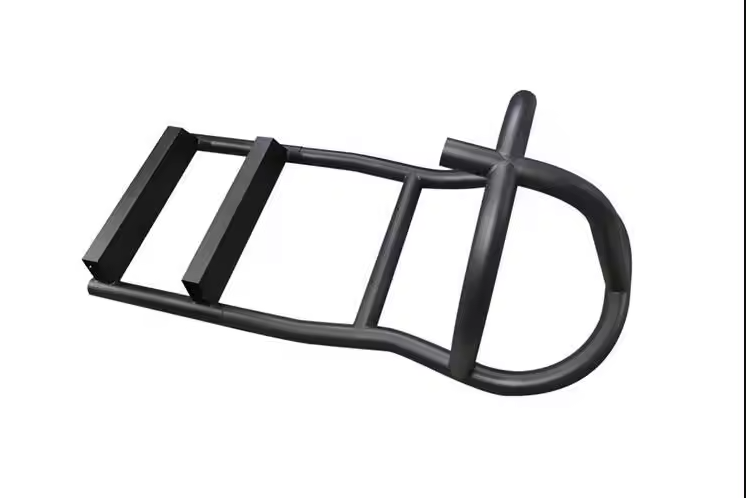

3. Mandrel Pipe Bending Equipment:

To achieve precise and consistent results in mandrel bending, specialized equipment is employed. The key equipment used in mandrel bending includes:

a. Pipe Bending Machine:

This machine is the heart of the process and provides the leverage and force required to bend the pipe. It features a hydraulic or mechanical system, along with various tooling options, depending on the specific application.

b. Mandrels:

Mandrels come in various shapes and sizes and are used to support the pipe’s inner surface during bending. They are typically made of tool steel, aluminum, or nylon, ensuring smooth and wrinkle-free bends. Mandrels can be customized according to the desired pipe specifications.

c. Bend Dies:

Bend dies determine the shape and radius of the bend. They are interchangeable and available in different sizes, accommodating various pipe diameters and bend angles.

4. Materials Used in Mandrel Bending:

Mandrel bending can be applied to a wide range of materials, including:

a. Metal Alloys:

Stainless steel, carbon steel, aluminum, and copper alloys are commonly bent using mandrel bending techniques. Different alloys require specific considerations such as wall thickness, ductility, and the use of lubricants to achieve optimal results.

b. Plastics:

Certain plastics, such as PVC, ABS, and polyethylene, can also undergo mandrel bending. However, the process may require lower temperature settings and specialized mandrels to prevent material degradation.

5. Applications of Mandrel Bending:

Mandrel bending finds extensive applications in various industries, including:

a. Construction:

Mandrel bending is used to create curved architectural structures, handrails, and artistic designs in buildings.

b. Automotive:

It is employed in exhaust systems, roll cages, and custom car modifications.

c. Aerospace:

Mandrel bending is utilized in aircraft fuel systems, hydraulic lines, and engine exhaust systems.

d. Oil and Gas:

Pipelines, storage tanks, and offshore platforms often incorporate mandrel bending for efficient fluid transportation.

e. Furniture and Decor:

Mandrel bending allows for the creation of unique furniture designs and decorative elements.

Conclusion:

It is a versatile and efficient process that enables the creation of curved pipes without sacrificing their structural integrity. By utilizing various bending techniques, specialized equipment, and a wide array of materials, mandrel pipe bending finds applications in diverse industries. Understanding the art of mandrel pipe bending provides professionals and enthusiasts with the knowledge to execute precise and aesthetically pleasing pipe designs.