Classification Of Metal Materials

June 10, 2022

Custom Metal Tube Bending

August 16, 2022The Properties Of Steel Materials

The properties of steel materials mainly refer to mechanical properties, physical properties, chemical properties and process properties.

(1) Mechanical properties

The mechanical properties of steel materials refer to the characteristics of steel materials under the action of external forces, such as strength, hardness, plasticity and impact toughness, etc. See Table 1-24 for details.

Table 1-24 terms of mechanical properties of common metal materials

| Terminology | Symbol | Paraphrase |

| Elastic modulus | E | The young’s joint is a special case of elastic modulus under normal stress and linear strain |

| Poisson’s ratio | v | The negative ratio of the general strain to the corresponding axial strain caused by the axial stress of the mining lower than the material ratio |

| Elongation | A | Percentage of elongation of original gauge length (or reference length) to original gauge length (or reference length) |

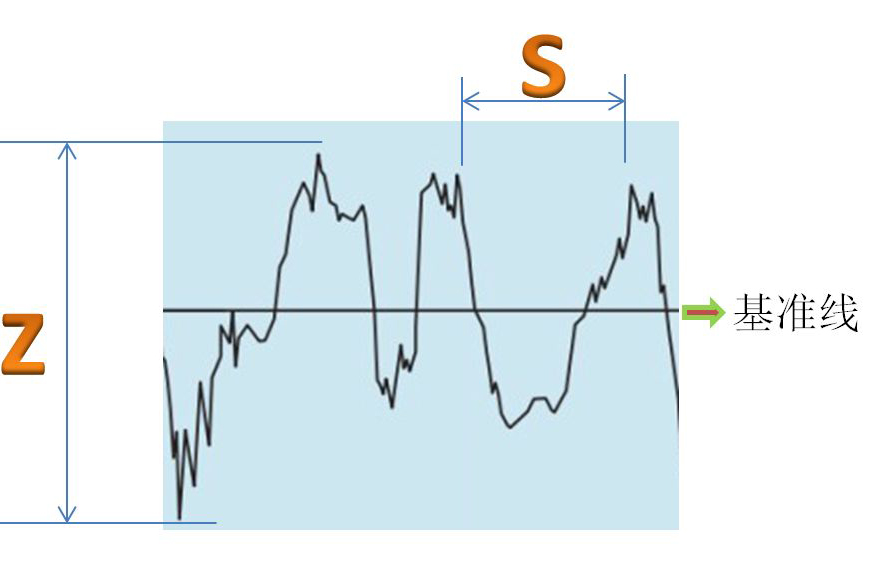

| Rate of reduction in area | Z | Percentage of the ratio of the maximum reduction of the cross-sectional area of the specimen to the original cross-sectional area after fracture |

| Tensile strength | Rm | And the maximum force F.Corresponding stress |

| yield strength | When the metal materials show the phenomenon of clothing, plastic deformation will occur during the test and the stress will not increase.The upper yield strength and the lower yield strength should be distinguished | |

| Upper yield strength | Reh | The maximum stress value of the specimen before the first decrease of yield stress |

| Lower yield strength | ReL | The minimum stress value during yield without considering the initial instantaneous effect |

| Specified non proportional extension strength | Rp₀.₂ | The stress when the nonproportional elongation is equal to the specified percentage of the gauge length of the extensometer.The symbols used should be accompanied by the following footnotes indicating the percentage specified, e.g. R |

| Non specified compressive strength | Rpc₀.₂ | The compressive stress when the non proportional compression deformation of the gauge length reaches the specified percentage of the original gauge length.The symbols used shall be accompanied by the following footnotes indicating the percentage specified, e.g. R, |

| Specified residual tensile strength | Rr₀₂ | The stress corresponding to the residual elongation after stress relief is equal to the specified percentage of extensometer gauge length.The symbols used shall be accompanied by the following footnotes indicating the percentage specified, e.g. ruler, |

| Brinell hardness | HBW | A measure of the resistance of a material to permanent indentation deformation by the application of a test force through a cemented carbide ball indenter |

| Knoop hardness | HK | Diamond indentation resistance per unit of pressure exerted by a diamond indenter |

| Martensite hardness | HM | A unit of measure for the resistance of a material to plastic and elastic deformations due to the application of a test force through a diamond cone (tetragonal or triangular pyramid) indenter |

| Rockwell hardness | HR | A measure of the resistance of a material to permanent indentation deformation caused by the application of a test force through a cemented carbide or steel ball indenter or a diamond cone indenter corresponding to a scale |

| Vickers hardness | HV | A measure of the resistance of a material to permanent indentation deformation caused by the application of a test force through a diamond Quad cone indenter |

| Dietmar Leeb | HL | The impact body of specified quality is used to impact the sample surface at a certain speed under the action of elastic force. The hardness value is calculated by the ratio of rebound speed and impact speed of punch at 1 mm from the sample surface |

Note: this table is extracted from the terminology of mechanical properties test of metallic materials (B 10623-2008).

(2) Physical properties

The physical properties of iron and steel materials refer to the density, melting point, thermal expansion, thermal conductivity, electrical conductivity and magnetic properties of the metal, and their codes and meanings are shown in Table 1-25 and Table 1-26.

Table 1-25 codes and meanings of physical properties of iron and steel materials

| Name | Meaning | Unit |

| Density (P) | The mass of metal per unit volume P < 5×10 ‘is called light metal, P > 5×10’ is called heavy metal | kg/m’ |

| melting point | The incubation temperature of the fusible metal, gold wind or alloy.Tungsten, molybdenum, complex and vanadium belong to rare metals, while tin, lead and zinc belong to | C |

| Thermal expansion (coefficient of linear expansion) (a) | It indicates that when a metal or alloy is heated, its volume increases and when it cools, it shrinks.The thermal expansion coefficient is used as the expansion coefficient | C-1 |

| Thermal conductivity (thermal conductivity) (2) | The results show that when the temperature is 0.9, aluminum is 0.5, and iron is 0.15, the thermal properties can be transferred | W/(m*K) |

| Electrical conductivity | Metal can conduct electric current.The best conductivity is silver, followed by copper and pin | |

| magnetic | Metal can guide the performance of the foundation, the metal with magnetic conductivity can be attracted by a magnet |

Table 1-26 thermal conductivity and linear expansion coefficient of common materials

| Material | Thermal conductivity W/(m·K) | Coefficient of linear expansion α/℃ |

| Add material 45 steel | 0.115 | 12 |

| Gray cast iron | 0.12 | 8.7~11.1 |

| brass | 0.14~0.58 | 18.2~ 20.6 |

| Red copper | 0.94 | 19.2 |

| Tin bronze | 0.14~0.25 | 17.5~19 |

| aluminium alloy | 0.36 | 24.3 |

| stainless steel | 0.039 | 15.5~16.5 |

(3) chemical properties

The ability of steel to resist various chemical effects at room temperature or high temperature is called chemical properties, such as corrosion resistance and chemical stability, and their names and meanings are shown in Table 1-27.

Table 1-27 types and meanings of chemical properties of iron and steel materials

| Name | Meaning |

| Corrosion resistance | The ability of iron and steel materials to resist the erosion of various media (such as atmosphere, water vapor, other harmful gases, acid, alkali, salt, etc.) |

| Oxidation resistance | The ability of metal materials to resist oxidation at high temperature |

| chemical stability | The sum of corrosion resistance and oxidation resistance of steel materials.The chemical stability of steel materials at high temperature is also called thermal stability |

(4) Process performance

The properties of iron and steel materials that are easy to process and form are called process properties, such as casting properties, forging properties, welding properties, machining properties and heat treatment process properties, etc. Their names and meanings are shown in Table 1-28.

Table 1-28 meaning of technological properties of iron and steel materials

| Name | Meaning |

| Castability | Whether iron and steel can be made into excellent casting properties by casting method, including liquid fluidity of metal, shrinkage rate during cooling, etc |

| Forging properties | The oxidation resistance of steel in forging and the properties of oxide scale, cold heading and cooling requirements after forging are also discussed |

| Weldability | Whether iron and steel is easy to explode into excellent joint performance by certain welding method.The good weldability material can obtain the weld without cracks, pores and other defects, and the welded joint has certain mechanical properties |

| Cutting performance | The difficulty of steel cutting |

| Heat treatment performance | Hardenability, deformation, cracking and brittleness of steel during heat treatment |

As a sheet metal fabrication manufacturer, we need to know very well about the Materials Properties,which help a lot for the effective production and good quality.