Custom Metal Fabrication Manufacturer

May 12, 2023

Metal Fabricating Services

May 23, 2023The Ultimate Guide to Metal Fabrication: What It Is and How It Works

Metal fabrication is a complex process that involves the manipulation of metal materials to create a wide variety of products. It is a vital industry that has played a central role in the development of modern infrastructure and technology. In this article, we will explore what metal fabrication is, how it works, and the various techniques used in the process.

What is Metal Fabrication?

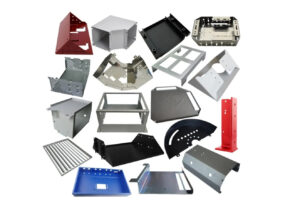

Metal fabrication is the process of transforming raw metal materials into a finished product. It involves cutting, bending, welding, and shaping metal, using a variety of tools and techniques. The process can be used to create a wide range of products, from small parts to large structures.

The Metal Fabrication Process:

The metal fabrication process begins with the selection of raw materials, which can include steel, aluminum, copper, and other metals. The metal is then cut to size, using tools such as saws, shears, and plasma cutters. The metal is then bent or shaped, using techniques such as press braking or roll forming.

Once the metal has been cut and shaped, it is often welded together using a variety of techniques, such as MIG welding or TIG welding. The welding process involves melting the metal at the joint and then allowing it to cool and solidify, creating a strong bond between the two pieces.

After the welding process, the metal may be finished using techniques such as sandblasting, powder coating, or painting. These finishing techniques help to protect the metal from corrosion and improve its appearance.

Types of Metal Fabrication Techniques:

There are many different techniques used in metal fabrication, including:

1. Cutting: The process of cutting metal involves using a variety of tools, such as saws, shears, and plasma cutters, to cut the metal into the desired shape and size.

2. Bending: Bending involves using tools such as press brakes or roll formers to shape the metal into a specific shape or angle.

3. Welding: Welding involves melting the metal at the joint and then allowing it to cool and solidify, creating a strong bond between the two pieces.

4. Finishing: Finishing techniques such as sandblasting, powder coating, or painting are used to protect the metal from corrosion and improve its appearance.

Applications of Metal Fabrication:

Metal fabrication is used in a wide range of industries, including construction, automotive, aerospace, and manufacturing. It is used to create a variety of products, from small parts to large structures.

In the construction industry, metal fabrication is used to create structural steel components such as beams and columns. In the automotive industry, metal fabrication is used to create parts such as chassis, engine components, and body panels.

In the aerospace industry, metal fabrication is used to create components such as aircraft frames and landing gear. In the manufacturing industry, metal fabrication is used to create a wide range of products, from machinery components to consumer products.

Conclusion:

Metal fabrication is a complex process that plays a vital role in the development of modern infrastructure and technology. It involves cutting, bending, welding, and shaping metal, using a variety of tools and techniques. Metal fabrication is used in a wide range of industries, from construction to aerospace, and is used to create a wide range of products, from small parts to large structures. Understanding the metal fabrication process is essential for anyone working in these industries or interested in the manufacturing process.