What is metal fabrication

May 23, 2023

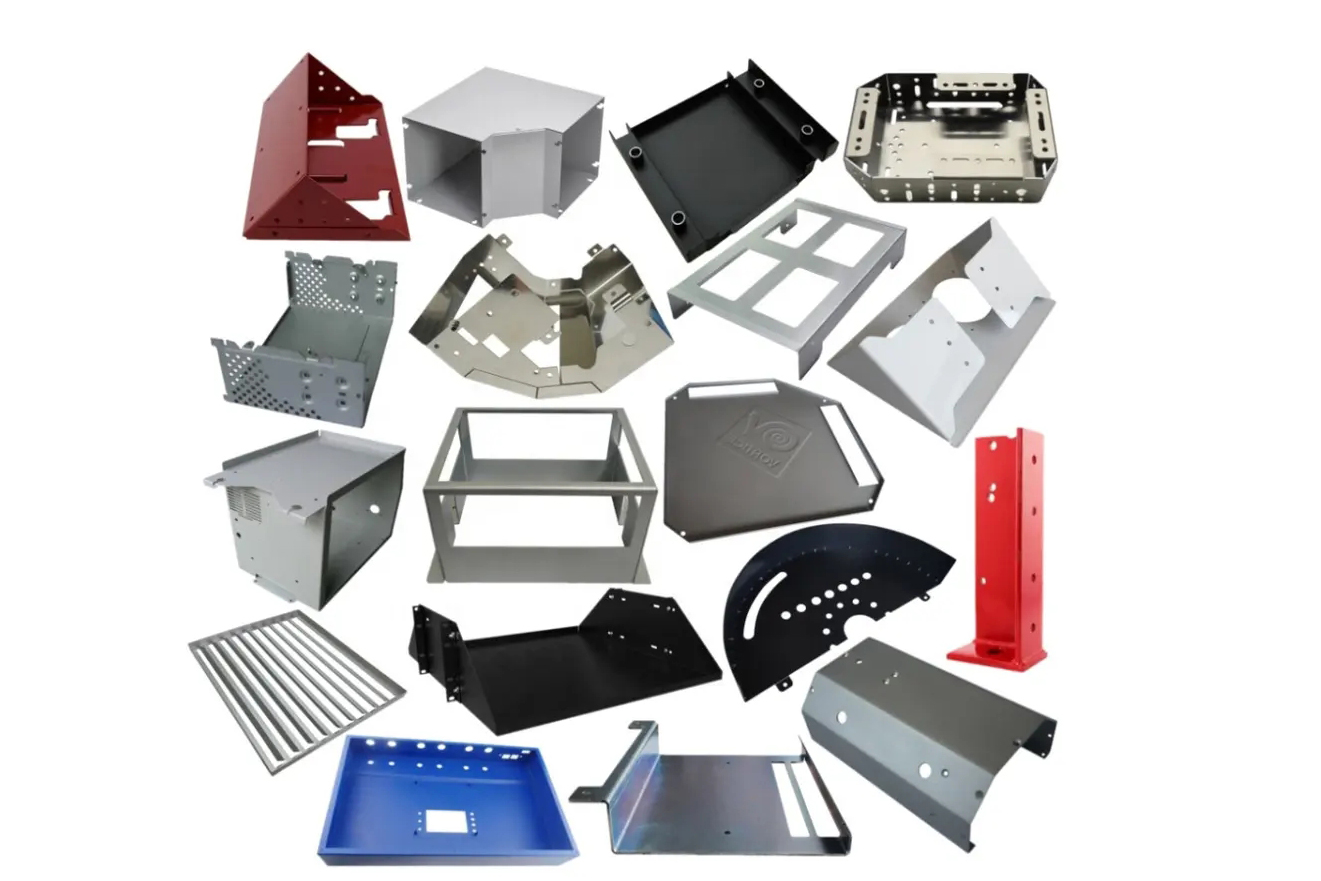

Metal Fabrication Services

May 23, 2023Metal Fabricating Services: The Ultimate Guide to Understanding Your Options

Metal fabrication is a process that involves the creation of metal structures by cutting, bending, and assembling raw materials according to specific designs. It is a complex process that requires specialized knowledge, skills, and tools. In this post, we will explore the different types of metal fabricating services available to help you understand which option is best for your needs.

Metal fabrication is a process that involves the creation of metal structures by cutting, bending, and assembling raw materials according to specific designs. It is a complex process that requires specialized knowledge, skills, and tools. In this post, we will explore the different types of metal fabricating services available to help you understand which option is best for your needs.

Sheet Metal Fabrication

Sheet metal fabrication involves the creation of metal structures by cutting, bending, and shaping thin sheets of metal. This process is commonly used in the production of metal parts for various industries, such as automotive, aerospace, and construction. Sheet metal fabrication can be performed using a variety of techniques, including laser cutting, punching, and stamping.

Laser Cutting

Laser cutting is a technology that uses a high-powered laser to cut through metal sheets. This process is highly precise, and it can be used to cut intricate patterns and shapes. Laser cutting is commonly used in the production of metal parts for the automotive, aerospace, and electronics industries.

Punching

Punching is a metal fabrication technique that involves the creation of holes in metal sheets using a punching machine. The machine punches the metal sheet with a die, creating the desired hole size and shape. Punching is commonly used in the production of metal parts for the automotive, construction, and electronics industries.

Stamping

Stamping is a metal fabrication technique that involves the creation of shapes in metal sheets using a stamping machine. The machine presses the metal sheet with a die, creating the desired shape. Stamping is commonly used in the production of metal parts for the automotive, aerospace, and electronics industries.

Welding

Welding is a metal fabrication technique that involves the joining of metal parts by melting the edges and fusing them together. Welding can be performed using a variety of techniques, including TIG welding, MIG welding, and spot welding. Welding is commonly used in the production of metal structures for the construction, automotive, and aerospace industries.

TIG Welding

TIG welding is a welding technique that uses a non-consumable tungsten electrode to create an arc between the electrode and the metal parts being joined. TIG welding is a precise and clean welding technique that is commonly used in the production of metal parts for the aerospace and electronics industries.

MIG Welding

MIG welding is a welding technique that uses a consumable wire electrode to create an arc between the electrode and the metal parts being joined. MIG welding is a fast and efficient welding technique that is commonly used in the production of metal parts for the construction and automotive industries.

Spot Welding

Spot welding is a welding technique that involves the creation of a series of welds between two metal parts. The welds are created by passing an electrical current through the metal parts, causing them to melt and fuse together. Spot welding is commonly used in the production of metal parts for the automotive and electronics industries.

CNC Machining

CNC machining is a metal fabrication technique that involves the use of computer-controlled machines to create metal parts. The machines can perform a variety of operations, including drilling, milling, and turning. CNC machining is commonly used in the production of metal parts for the aerospace, automotive, and electronics industries.

Drilling

Drilling is a machining technique that involves the creation of holes in metal parts using a drill bit. The drill bit is rotated at high speed, creating the desired hole size and shape. Drilling is commonly used in the production of metal parts for the automotive, construction, and electronics industries.

Milling

Milling is a machining technique that involves the creation of shapes in metal parts using a rotating cutting tool. The cutting tool removes material from the metal part, creating the desired shape. Milling is commonly used in the production of metal parts for the aerospace, automotive, and electronics industries.

Turning

Turning is a machining technique that involves the creation of cylindrical shapes in metal parts using a rotating cutting tool. The cutting tool removes material from the metal part, creating the desired shape. Turning is commonly used in the production of metal parts for the automotive, construction, and electronics industries.

Metal Fabricating Conclusion

In conclusion, metal fabrication is a complex process that requires specialized knowledge, skills, and tools. There are many different types of metal fabricating services available, including sheet metal fabrication, welding, and CNC machining. Each option has its own advantages and disadvantages, and it is important to choose the right option for your needs. By understanding the different types of metal fabrication services available, you can make an informed decision that will help you achieve your goals.