Injection Molded Plastic Parts

March 17, 2023

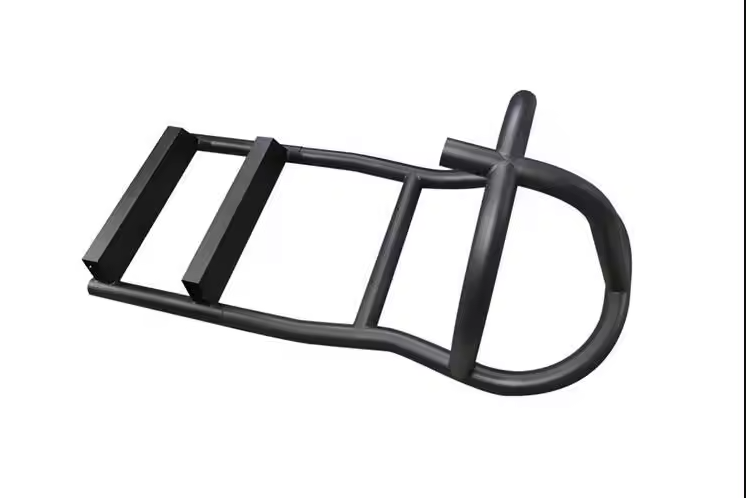

Pipe Bending Manufacturer

May 11, 2023What’s Pipe Bending?

Pipe Bending and Fabrication is the most commonly used method for bending pipes during use. According to the different bending equipment, it can be divided into two types: bending by pipe bender and manual bending. When making models, the latter will not require special bending equipment, and the device for bending pipes is very simple and low in manufacturing cost. It is easy to adjust and use during use, and is mainly used in small batch production situations.

Pipe Bending and Fabrication is the most commonly used method for bending pipes during use. According to the different bending equipment, it can be divided into two types: bending by pipe bender and manual bending. When making models, the latter will not require special bending equipment, and the device for bending pipes is very simple and low in manufacturing cost. It is easy to adjust and use during use, and is mainly used in small batch production situations.

There are many methods used in the processing of curved pipes. To some extent, according to the methods of bending and forming, they can be effectively divided into push bending, bypass bending, roll bending, and press bending. Their products can be effectively divided into mold bending and non mold bending according to whether they use a mold during bending.

Bend can be effectively divided into core bending and non core bending according to whether there is a core rod during bending, and can be divided into cold bending and hot bending according to whether there is heating during bending. In recent years, new bending processes such as zero radius bending, intermediate frequency induction bending, thermal stress bending, and laser forming bending have also emerged.

During the manufacturing process, the main method of roll bending is to use its three rollers, and then effectively bend its pipes. When used, its roll bending has certain requirements for the bending radius, which is only applicable to thick wall pipes with large radius of curvature, and it appears powerless for small radius bending.

The processing method and working principle of roll bending are basically the same as those of sheet metal roll bending during use, except that the roller used for tube roll bending has a working surface that matches the cross-sectional shape of the tube blank during operation. When bending, it is only necessary to change the spacing between the master and slave rollers to achieve various curvature radius bending. The roller wheel is the driving wheel, and the other two are driven wheels. This method is particularly suitable for bending circular or helical pipe fittings.

The bending accuracy of bent pipes is also one of the important factors that affect the quality of bent pipes to a certain extent. When manufacturing bent pipes for valves, in addition to controlling the specifications and dimensions within a certain tolerance range, users are also required to select corresponding bent pipes based on the bent pipe diameter when using them.

How to Bending or Fabrication Pipes and tube

In daily life, in work. Straight Pipe Bending and Fabrication may be pulled and bent into various shapes for use. The bend is bent by a complete set of bending molds. No matter what kind of mechanical equipment it is, it is mostly used for bending pipes, mainly for oil, gas, infusion sets, etc., and plays a more important role in aircraft and their engines. In such an important application, how much do we know about the process of bending pipes? The following editor will tell you five commonly used methods for pipe bending treatment.

1. Punching method:

Extend the pipe end to the desired size and shape, with a tapered core on the punch.

Second, bending forming method: There are three commonly used methods: one is stretching method, the other is stamping method, and the third is roller method, with 3-4 rollers, 2 fixed rollers, and 1 adjusting roller, adjusting the fixed roller pitch, and bending the finished pipe fittings.

2.Bulging method:

One method is to place rubber inside the pipe, and press the upper part with a punch to protrude the pipe; The other is hydraulic expansion, which fills the middle of the pipe with liquid, and the liquid pressure expands the elbow to the desired shape. Most corrugated pipes are produced using this method.

3.Forging method:

The pipe end or part is pulled out by a die forging machine to reduce the outer diameter of the pipe. The commonly used forging machines are rotary, connecting rod, and roller type. Roller type: placing the core inside the tube and pushing the roller outward, used for processing round edges.

4.Rolling method:

generally without mandrel, suitable for the inner edge of thick wall pipes.

First of all, there are two main types of bending process: hot bending and cold bending.

1. Hot bending pipe

The production process of hot bending pipe, also known as medium frequency bending pipe, belongs to the thermal expansion range.

Manufacturing of hot bends:

After cutting the material, the straight pipe is placed on the sensing ring of the curved part of the steel pipe, and the pipe head is stuck by the mechanical rotating arm. The intermediate frequency current is used to heat the steel pipe in the sensing ring. When the temperature of the steel pipe rises to the plastic state, the mechanical thrust of the steel pipe at the rear end of the steel pipe pushes the bending, and the bent part is quickly cooled with coolant, making the bent pipe continuously bend while heating, pushing, bending, and cooling.

Hot bends are mainly used in industries such as circular steel structures, tunnel support, roof curved beams, subway engineering, aluminum doors and windows, ceilings, packaging tube inner frames, balcony handrails, shower doors, production line tracks, fitness equipment, and so on.

2. Cold bending elbow

Production of cold bends:

Cold bending is a method of bending without heating or changing the material structure at room temperature.

Second: Use of bending

1. In various Pipe Bending and Fabrication, it is inevitable to use various bends, such as ship pipes, automobile oil pipes, and other pipelines. Compared to other types of bends, circular arc bends have many advantages. Firstly, various materials flow smoothly at the circular arc bends, with a small and uniform impact on the pipe wall; Secondly, the arc bend itself has small stress concentration, high strength, and high impact resistance;

With the rise of modern steel furniture, office chairs, beach chairs, luggage carts, shopping carts, child trolleys, cribs, and computer tables, several metal tubes form several bright lines, which are practical, convenient, safe, and reliable;

3. Air conditioning and refrigeration pipes mainly include bent pipes, small U-shaped pipes, and return bends;

The bathroom industry now has more and more bends, faucets, towel racks, and S-shaped accessories.

5. Motorcycles, automobiles, electric vehicles, bicycles, and other means of transportation, handlebars, bumpers, frames, etc;

6. Fitness equipment, lighting, construction machinery, and other industries.

Pipe Bending and Fabrication

|

Material

|

Aluminum, stainless steel, copper, brass, galvinized etc.

|

|

Size

|

Customized

|

|

Surface treatment

|

Powder coating, electroplating, oxide,anodization

|

|

Technics

|

|

|

Certification

|

ISO9001:2015

|

|

OEM

|

Accept

|

|

Drawing Format

|

3D/CAD/Dwg/IGS/STP

|

|

Color

|

Customized

|

|

Application

|

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications

|